(Integrated with GPLPAK’s Dental Implant Packaging Capabilities)

“Packaging is no longer just containment — it’s the first line of defense, a brand ambassador, and a pivotal part of the patient journey.”

In the realm of oral medical devices — including dental implants and clear aligners (e.g. Invisalign-style appliances) — packaging plays a critical role beyond mere protection and transport. It embodies brand promise, ensures sterility, and shapes user experience.

For B2B clients such as orthodontic brands, implant manufacturers, and medical device OEMs, choosing the right packaging solution is essential. In this article, we explore how to design superior aligner packaging that also integrates insights from dental implant packaging needs. Along the way, we introduce GPLPAK’s capabilities as your trusted packaging partner.

The sterile medical implant packaging market is expanding, with projections pointing to a 6–7% CAGR over the coming years.

Clear aligner technology is steadily gaining market share, driving demand for customized aligner packaging.

Key trends in medical device packaging include hygiene, traceability, intelligent packaging, and sustainable materials.

| Challenge | Description |

|---|---|

| Sterility & Contamination Control | Contaminants (particles, dust, organic residue) during packaging or transport can undermine clinical outcomes or patient safety. |

| Regulation & Compliance | Medical packaging must comply with ISO 11607, FDA, MDR, and other regional standards. |

| Brand Differentiation | Clients expect packaging to deliver brand identity, premium feel, and craftsmanship. |

| User Experience | Ease of unboxing, clear instructions, storage convenience — these affect perception and satisfaction. |

| Cost & Supply Chain Consistency | Premium materials and custom structures must still be cost-efficient and reliably scalable. |

Given these pressures, a well-engineered packaging solution that balances hygiene, branding, and experience becomes a competitive advantage.

For both dental implant packaging and aligner packaging, achieving and maintaining sterility is non-negotiable.

Use high barrier films / medical grade co-extrusions to block moisture, gases, and particulates.

Employ heat sealing, lamination, and barrier layers to ensure integrity during transport.

Incorporate tamper-evident features (tear strips, security seals, QR/NFC authentication).

Operate packaging in cleanroom environments (e.g. ISO 7 / ISO 8) to avoid introducing particles.

Pre-treatment of devices (e.g. plasma cleaning, surface activation) to reduce residues prior to packaging.

Seal integrity testing (vacuum, pressure, dye ingress) ensures packaging remains intact.

Particle / microanalysis (SEM, EDS, particle counters) validate that no foreign particles remain.

Accelerated aging & stress testing — temperature/humidity cycling, vibration, drop tests — confirm durability under shipping conditions.

By rigorously specifying materials, structure, environment, and validation, packaging truly becomes a sterile “shell” for the device.

Beyond function, packaging must communicate your brand’s identity and elevate perceived quality.

Spot gloss UV, UV varnish, selective coating to highlight logos or key design elements.

Soft-touch matte lamination, silk-films, textured papers to produce a premium tactile feel.

Color contrast, gradient designs, hidden interior artwork to surprise and delight upon opening.

Custom trays / inserts that precisely hold aligners or implants in place, reducing shifting and scratching.

Offer clinic-branded (practice-branded) packaging — let dentists or orthodontists feature their branding to patients, while the factory brand remains hidden.

Modular packaging suites (aligner tray + travel case + user guide) that maintain consistent visual language.

Customization options: logo placement, color schemes, surface effects, labeling — enabling clients to differentiate themselves in a crowded market.

By integrating branding deeply into the packaging design, you turn every unboxing into a brand experience.

Even the most functionally robust packaging can be undermined by poor usability. Good UX in packaging is a competitive edge.

Intuitive opening mechanisms (tear strips, pull tabs, hinge lids) reduce user frustration.

Clear labeling: side “upper / lower,” left vs right aligner cues, color coding when needed.

Re-closable features or carry cases help users store aligners between uses.

Layered unboxing: first layer reveals brand message / logo / welcome card.

Shock-absorbing tray designs to prevent damage in transport.

Minimal fingerprints, clean lines, easy-to-clean interior surfaces.

Consistent aesthetic — the moment a patient opens the box, they feel confidence in the product and brand.

When UX is designed well, patients subconsciously equate the packaging quality with treatment quality.

Although dental implant packaging and aligner packaging have distinct requirements, they can share core principles and infrastructure.

Shared cleanroom production & quality protocols

Reusable material frameworks & validation methods

Modular designs: common outer box with swappable internal trays (for implants, aligners, accessories)

Unified brand systems & visual identity across both product lines

By integrating both, packaging providers can offer clients a single vendor solution that reduces complexity, ensures consistency, and often lowers cost.

Here, we position your company strengths, credibility, and partnership value.

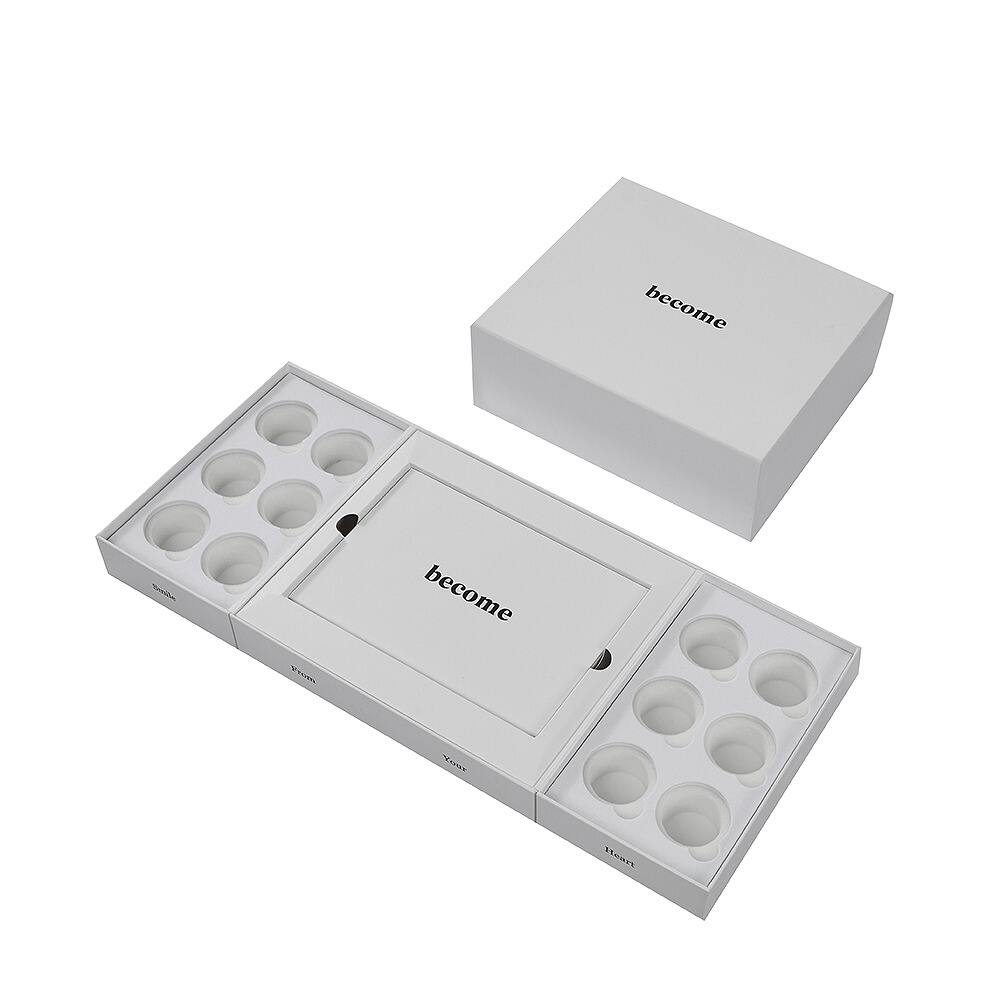

GPLPAK (Dongguan Liyuan Packaging Products Co., Ltd.) specializes in custom rigid boxes, magnetic boxes, drawer-style boxes, and complex structural packaging. Visit us at gplpak.com.

In the medical / dental device sphere, GPLPAK brings:

Full custom structural design (trays, inserts, slotting)

High-end finishing: soft-touch lamination, selective UV, embossing/debossing, foil stamping

Compliance-ready materials, eco-certified options (FSC, RoHS)

Scalable, stable manufacturing and supply chain

Capability for sterile packaging design (e.g. barrier films, heat-seal structures, tamper features)

While many GPLPAK cases are in luxury packaging, the same design & engineering capabilities apply to medical / dental packaging. A client in orthodontics could commission GPLPAK for an aligner kit box (tray + travel case + user insert), all in unified visual identity and robust materials.

Requirement Gathering & Sample Submission — client shares aligner or implant prototypes + branding assets

Concept & Structural Design — 3D renders, dielines, material recommendations, cost estimates

Prototype Production & Review — create physical sample, test usability, durability

Validation Testing — seal integrity, contamination, aging, drop/vibration tests

Mass Production & QC — inline quality checks, traceability, packaging logistics

After-sales & Iteration — client feedback, version improvements, packaging upgrades

With GPLPAK’s robust process and medical packaging know-how, you get consistency, reliability, and design flexibility.

Premium packaging that balances hygiene, branding, and user experience is no longer optional — it’s a critical differentiator in the competitive world of implant and aligner devices.

GPLPAK is here to partner with you. Our expertise in structural design, high-end finishing, medical compliance, and scalable production makes us well-suited to support your dental implant packaging and aligner packaging projects.

Next Steps:

Contact us for a free consultation and initial structural layout

Send us your device samples for customized proposals

Request a visual mockup or cost analysis tailored to your brand

Author :Suka

Suka is a Senior Packaging Specialist at GPLPAK. Passionate about innovative packaging solutions and sustainable practices, Suka is committed to helping brands shine through distinctive and effective packaging strategies. With deep expertise in design trends and industry insights, Suka provides actionable guidance to entrepreneurs, creatives, and business leaders, ensuring their packaging is not only visually appealing but also environmentally responsible. Suka excels at turning concepts into practical solutions that connect with consumers and elevate brand success.

Email:[email protected]

Whatsapp:+86 13723519895

Hot News

Hot News2025-05-27

2025-09-10

2025-07-28

2025-07-30

2025-08-03

2025-08-06