4 Top Inlay Solutions for Custom Whisky Boxes — Materials & Benefits Explained

In the world of alcohol packaging, the inlay inside a whisky box plays a crucial role. Beyond securing the bottle during transit and storage, a well-designed inlay enhances the overall presentation and perceived value of the product.

When customizing inlays for whisky boxes, choosing the right material is essential. Factors such as bottle size, weight, and branding requirements all influence the ideal solution. In this article, we’ll explore the four most popular inlay types used in rigid whisky boxes — and outline the benefits of each to help you find the perfect match.

1. Cardboard & Greyboard Inlay

Eco-friendly, budget-friendly, best for small bottles

Cardboard and greyboard inlays are among the most commonly used solutions for whisky boxes. Made from recyclable paperboard and grey chipboard, they strike a balance between sustainability and cost-efficiency.

Benefits:

Low production cost — ideal for startups or price-sensitive markets

Easy to die-cut for precise fitting

Suitable for small or lightweight bottles

Fully recyclable and customizable with printed finishes

✅ Best for: Simple, small-sized whisky bottles and brands seeking eco-conscious packaging on a budget.

Below is an example of drawer shaped XO box,outside is texture paper and gold paper inside,pull ribbon handle.

Insert is rigid paper greyboard insert,because client request eco-friendly,but bottle can be held very well.

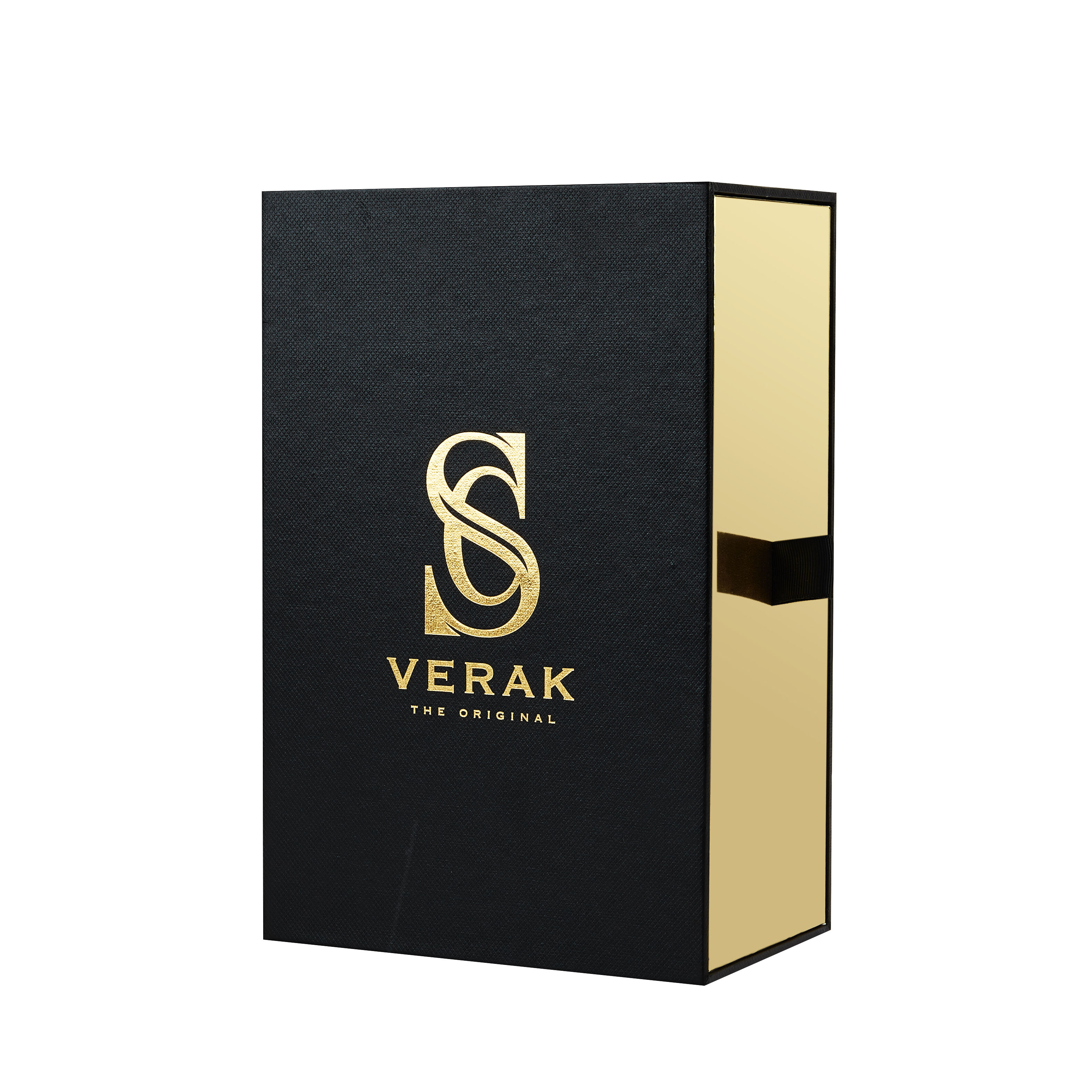

2. Molded Pulp Inlay

Sustainable and cost-effective for mass production

Molded pulp inlays are crafted from natural fiber materials and offer excellent cushioning performance. While the per-unit cost is low, initial mold costs are relatively high — making this option ideal for long-term production runs.

Benefits:

Biodegradable and environmentally friendly

Excellent shock absorption

Stackable and nestable for efficient storage

Smooth surface texture for clean presentation

✅ Best for: Large-scale whisky brands focused on sustainability and long-term volume production.

Pulp tray insert have high MOQ and high tooling cost,but molded pulp inserts are crafted from biodegradable agricultural fibers — most commonly bagasse, a byproduct of sugarcane.

Types of Pulp Inserts: Dry Press vs. Wet Press

1.Dry-Pressed Pulp (Dry Molded Pulp) :Rough and fibrous texture

2. Wet-Pressed Pulp (Wet Molded Pulp):Smooth, dense, and white surface — suitable for high-end packaging

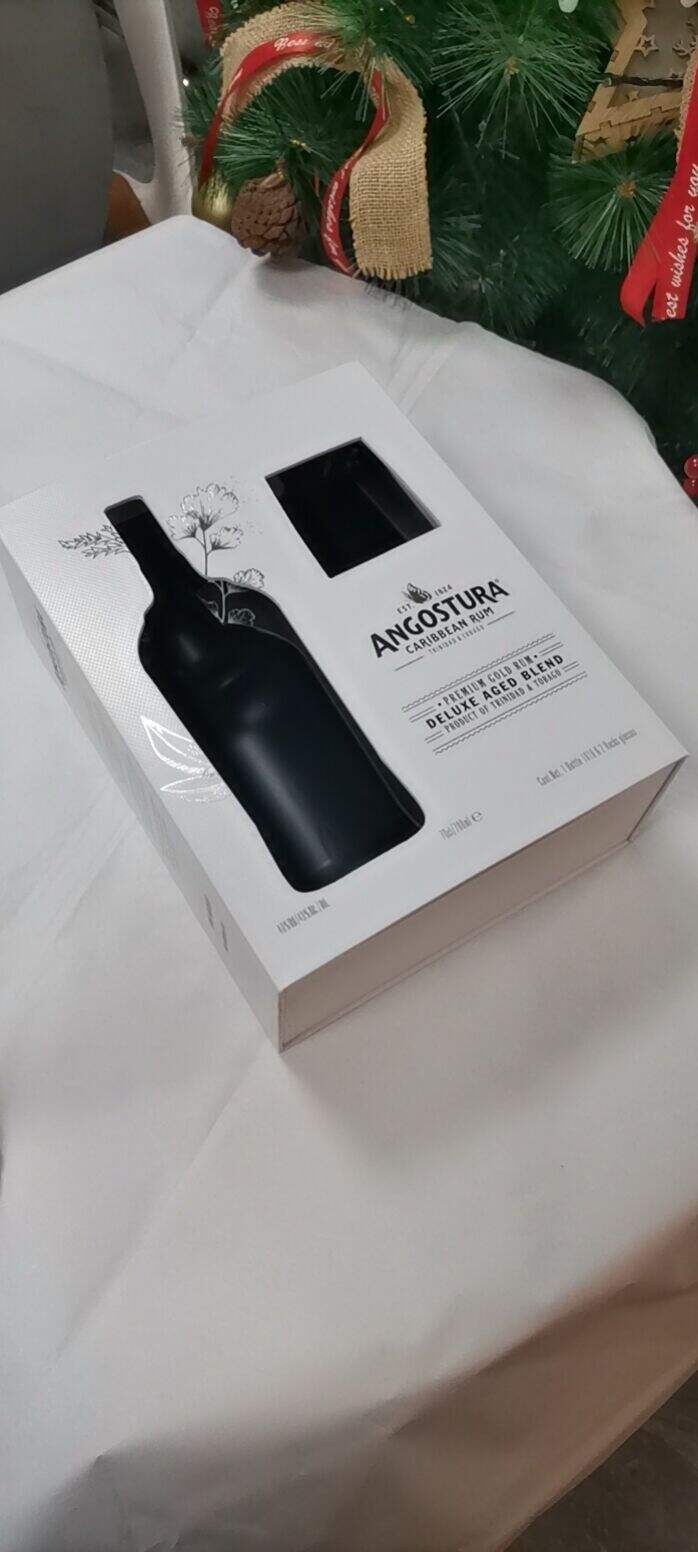

3. Thermoformed Plastic (Blister) Inlay

Strong grip, fast turnaround, cost-efficient

Blister inlays are formed by heating plastic sheets and vacuum-molding them to the shape of your bottle. They offer excellent hold and precision while being very affordable and easy to produce.

Benefits:

Low tooling costs — great for short runs or seasonal promotions

Fast lead time from design to production

Excellent bottle stabilization during transport

Transparent or colored options available

✅ Best for: Limited-edition or budget-conscious whisky lines needing quick, secure packaging.

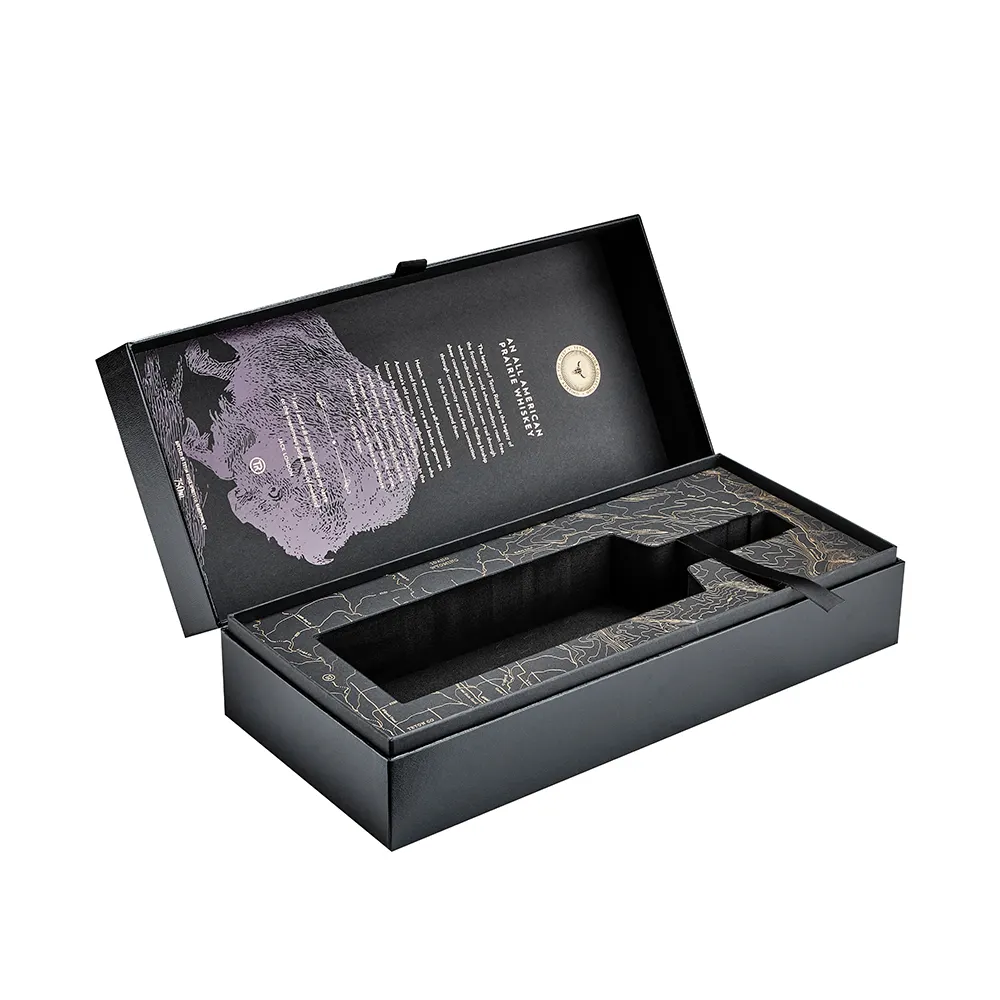

See below box,it is black blister insert.Normally we can do clear transparent plastic insert,white and black,other colors will have high MOQ.

4. EVA Foam Inlay

Maximum protection for premium and heavy bottles

EVA (Ethylene-Vinyl Acetate) foam inlays offer unmatched cushioning, flexibility, and shock resistance. They're ideal for premium packaging where both protection and luxury aesthetics are top priorities.

Benefits:

High elasticity and density for optimal shock absorption

Can be laminated with velvet or fabric for a premium look

Custom CNC cutting for precise bottle fit

Available in various colors and thicknesses

✅ Best for: High-end, large-format whisky bottles and export packaging requiring premium protection.

EVA insert we can put paper on top cover or velvet on top to make insert looks more luxury.

By aligning your packaging inlay with your product’s needs, you can significantly improve safety, branding, and customer experience — while optimizing production costs.

✉️ Need help developing custom inlays for your whisky packaging?

Contact our packaging experts today for a free consultation and structural sample!

View our portfolio → [www.dhpfactory.com]

Get a quote → [ Contact Us via email:[email protected] ]