Innovative Packaging Solutions That Won't Break the Bank

In today's competitive market, creative packaging has become a crucial differentiator for brands seeking to capture consumer attention while maintaining reasonable costs. Companies are increasingly discovering that innovative packaging solutions don't necessarily require enormous budgets. By combining strategic design thinking with smart material choices, businesses can achieve remarkable results that both delight customers and protect profit margins.

The challenge lies in finding the sweet spot between creativity and cost-effectiveness. Forward-thinking brands are revolutionizing their approach to packaging by embracing sustainable materials, minimalist designs, and clever structural solutions that maximize impact while minimizing expenses. This comprehensive guide explores practical strategies for achieving memorable creative packaging without excessive spending.

Essential Elements of Cost-Effective Package Design

Material Selection and Optimization

Choosing the right materials forms the foundation of cost-effective creative packaging. Consider alternatives like recycled cardboard, lightweight polymers, or innovative biodegradable options that offer both environmental benefits and cost savings. Smart material selection often involves analyzing the entire supply chain to identify opportunities for optimization.

Many successful brands have found that using fewer materials more intelligently can lead to better results. For instance, reducing packaging thickness by just a few millimeters can generate significant savings when scaled across thousands of units, while clever structural design ensures product protection remains uncompromised.

Streamlined Production Processes

Efficient production methods play a vital role in controlling packaging costs without sacrificing creativity. Digital printing technologies now enable smaller minimum order quantities and faster turnaround times, making creative packaging more accessible to businesses of all sizes. By optimizing production runs and minimizing waste, companies can allocate more resources to design innovation.

Consider implementing standardized components that can be customized through printing or labels rather than requiring entirely unique structural elements. This approach reduces tooling costs while maintaining the flexibility to create distinctive packaging solutions.

Design Strategies for Maximum Impact

Minimalist Aesthetics

Embracing minimalist design principles can significantly reduce costs while creating sophisticated, eye-catching creative packaging. Simple, bold graphics and carefully chosen color schemes often prove more effective than complex, multi-component designs. This approach not only minimizes production expenses but can also create a more premium brand perception.

Focus on one or two standout design elements rather than trying to incorporate multiple features. This targeted approach often yields better results and helps control costs by limiting the number of production processes required.

Versatile Design Systems

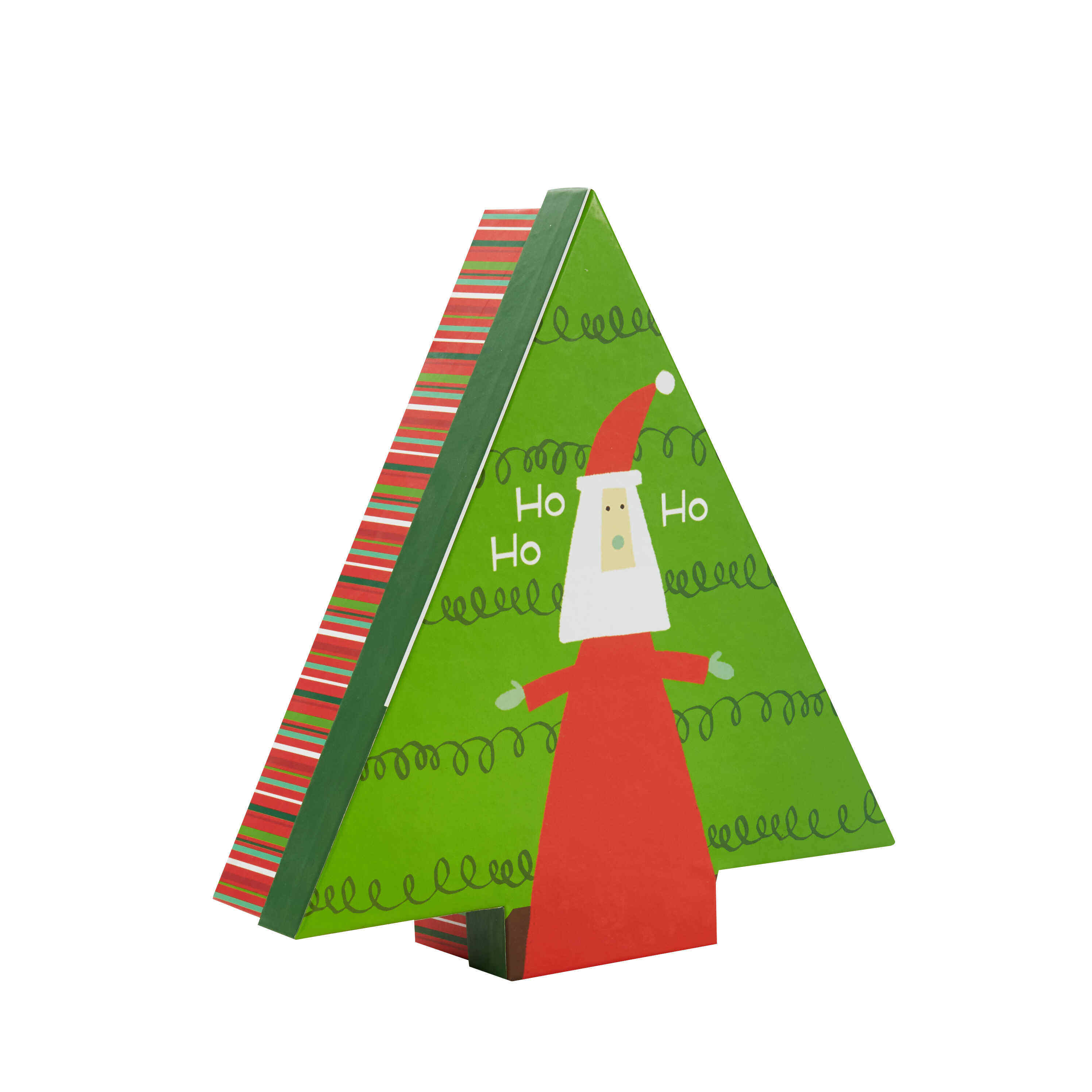

Developing flexible design systems allows for creative packaging variations while maintaining cost efficiency. Create templates that can be easily adapted for different products or seasonal promotions without requiring complete redesigns. This approach reduces design costs while ensuring brand consistency across product lines.

Consider how packaging designs can be modified through simple color changes or graphic overlays, allowing for product differentiation without the expense of creating entirely new packaging structures.

Sustainable Solutions for Long-Term Savings

Eco-Friendly Materials and Methods

Incorporating sustainable materials into creative packaging design often leads to both environmental benefits and cost savings. Recycled materials typically cost less than virgin materials, while lighter-weight options reduce shipping expenses. Many consumers also prefer environmentally conscious packaging, potentially increasing sales and brand loyalty.

Research innovative materials that offer multiple benefits, such as biodegradable alternatives that may qualify for tax incentives or materials that require less energy during production, reducing overall costs.

Waste Reduction Strategies

Implementing effective waste reduction strategies in packaging design and production can significantly impact the bottom line. Consider designs that maximize material usage and minimize offcuts. Digital prototyping and sampling can reduce physical waste during the development phase.

Analyze your entire packaging lifecycle to identify opportunities for reducing waste and recovering materials. Even small improvements in material efficiency can lead to substantial cost savings when implemented across large production runs.

Leveraging Technology for Cost Efficiency

Digital Design Tools

Modern design software and digital tools enable rapid prototyping and testing of creative packaging concepts without the expense of physical samples. Virtual reality and augmented reality technologies allow for detailed visualization and refinement of designs before committing to production.

Utilize parametric design tools to quickly generate multiple variations and optimize designs for both aesthetic appeal and production efficiency. This approach reduces development time and associated costs while encouraging innovation.

Smart Production Technologies

Advanced production technologies can significantly reduce costs while enabling more creative packaging solutions. Automated systems, smart manufacturing processes, and quality control technologies help minimize errors and waste while maintaining consistent quality.

Investigate emerging technologies like 3D printing for prototypes and small production runs, or digital printing systems that eliminate the need for minimum order quantities, making creative packaging more accessible for smaller brands.

Frequently Asked Questions

How can small businesses achieve creative packaging on a limited budget?

Small businesses can focus on simple but effective design elements, utilize digital printing for smaller quantities, and consider stock packaging options that can be customized through labels or sleeves. Working with experienced packaging designers who understand cost constraints can help identify creative solutions within budget limitations.

What are the most cost-effective sustainable packaging materials?

Recycled cardboard, paper-based materials, and certain bioplastics often offer the best balance of cost and sustainability. These materials typically have established recycling infrastructure and can be sourced at competitive prices while meeting environmental objectives.

How can companies balance creativity with production efficiency?

Companies should focus on designs that can be produced using standard equipment and processes while incorporating creative elements through printing, finishing, or structural innovations. Developing modular design systems and utilizing digital prototyping can help optimize both creativity and production efficiency.

When is it worth investing in custom packaging solutions?

Custom packaging investments are typically justified when they provide significant competitive advantage, protect unique products more effectively, or create memorable unboxing experiences that drive customer loyalty and word-of-mouth marketing. Careful cost-benefit analysis should guide these decisions.