When your brand decides to upgrade from ordinary folding cartons to luxury rigid paper boxes, one of the first questions that arises is:

👉 “How much does a custom rigid paper box cost?”

In this article, we’ll break down the real pricing factors, show typical cost ranges, and explain how working with GPLPAK — a professional luxury packaging manufacturer — can help you balance quality, budget, and brand value. Whether you’re in the wine, cosmetics, jewelry, or premium gift industry, this guide will give you a clear understanding of what to expect before requesting a quote.

Rigid boxes (also known as hard boxes or setup boxes) are different from standard folding cartons due to their thicker structure, premium materials, and hand-crafted finishing.

Most rigid boxes use 2 mm–3 mm greyboard wrapped in specialty paper with embellishments such as hot stamping, embossing, magnetic closures, or velvet inserts.

In short, you’re not just paying for packaging — you’re investing in presentation, protection, and brand storytelling.

Key benefits of rigid boxes:

Superior product protection for fragile or luxury goods

Enhanced unboxing experience and perceived value

Reusable and durable — often retained by consumers as keepsakes

These attributes explain why rigid boxes typically cost more than standard paper packaging.

Based on current industry data and GPLPAK’s production experience:

Small quantities (≈ 500 pcs): USD 5 – 10 per box

Medium quantities (≈ 2 000 – 5 000 pcs): USD 2 – 5 per box

Large-scale production (10 000 pcs +): USD 1.5 – 3 per box

Note: Prices vary according to size, material, printing complexity, inserts, and finishing options.

As one of China’s trusted rigid paper box manufacturers, GPLPAK operates a 10 000 m² facility, with 200 + skilled workers and 20 + advanced machines, allowing high-volume cost optimization without compromising quality.

Learn more at GPLPAK Manufacturing.

Board thickness: 2 mm, 3 mm, 4 mm, or 5 mm — thicker boards raise the price.

Wrapping paper: From art paper to textured, metallic, or leather-wrapped materials — premium options cost more.

Surface finishing: Hot foil, spot UV, matte/gloss lamination, or soft-touch coating add tactile and visual value.

Inserts: EVA foam, molded pulp, velvet, or cardboard inserts vary in both price and perceived luxury.

Box style: Lift-off lid, magnetic closure, book-style, drawer, or foldable rigid structures all have unique assembly costs.

Size: Larger boxes require more material and labor.

Custom shapes: Round, hexagonal, or window-cut designs increase tooling and setup expenses.

Printing method: Offset, digital, or Pantone spot color affects ink and setup costs.

Post-press enhancements: Foil stamping, embossing, debossing, or die-cutting can increase price per unit.

Luxury touch: Soft-touch lamination, holographic foil, and magnetic closures provide premium feel but add cost.

Larger quantities significantly reduce per-unit cost since setup and tooling fees are distributed over more pieces.

At GPLPAK, the MOQ starts from 300 pcs, and the most common order volumes range from 500 – 3 000 pcs.

Automation, efficient workflow, and integrated logistics enable competitive pricing even for mid-range orders.

See details on GPLPAK Manufacturing Capabilities.

Shipping method (sea vs air), destination, and packaging method also influence the total cost.

Moreover, choosing eco-friendly materials (FSC-certified paper, biodegradable glue, soy-based inks) may slightly increase cost but aligns with global sustainability trends and enhances brand reputation.

GPLPAK’s factory is certified for FSC and BSCI, reflecting our commitment to responsible production.

Visit GPLPAK Factory Profile.

When you collaborate with GPLPAK, you benefit from more than just production — you gain a strategic packaging partner.

✅ End-to-end service: From structure design, sampling, and printing to assembly, QC, and global logistics.

✅ Strong manufacturing capacity: 10 000 m² factory, 20 + machines, 200 + craftsmen, and dedicated R&D team.

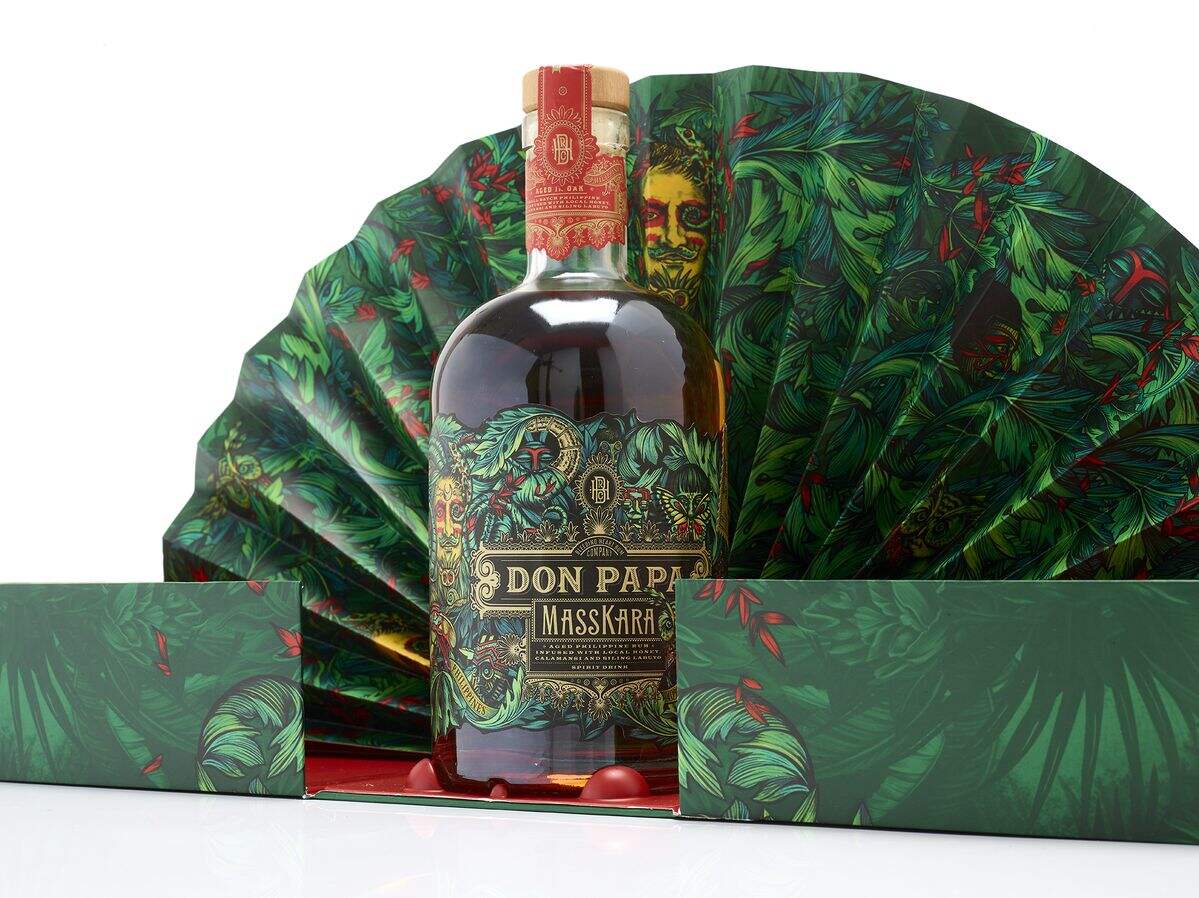

✅ Experience in luxury sectors: Serving global brands in wine & spirits, cosmetics, jewelry, and chocolate packaging.

✅ Eco-responsibility: Sustainable materials and processes integrated into every project.

✅ Flexible customization: Supports all rigid box types — lid-base, drawer, magnetic, book-style, foldable, or bespoke shapes.

✅ Transparent quotation: Clear material and process breakdown to help clients understand pricing logic.

With GPLPAK, you don’t just get a packaging supplier — you gain a partner that turns packaging into art.

As our slogan states: “Packaging of Art.”

Here’s a simplified overview of how rigid box pricing is typically calculated:

Confirm specifications: Size, structure, quantity, and insert type.

Select materials: Greyboard thickness, wrapping paper, and finishing effects.

Sampling & mold fee: First-time orders may require tooling or sample setup cost.

Production cost per unit: Based on materials, printing, and handwork.

Example: 500 pcs basic rigid boxes → around USD 4 – 6 each.

Example: 3 000 pcs same box → around USD 2.5 – 3.5 each.

Add logistics: Shipping, customs, and packaging.

Offer pricing options: Basic vs premium finishes to help clients compare cost-to-value ratio.

By working with GPLPAK, you can receive customized cost optimization suggestions to achieve the ideal balance between brand aesthetics and budget control.

Q1: What is the MOQ?

→ MOQ starts from 300 pcs for most rigid boxes. (Source: GPLPAK Manufacturing)

Q2: Can you produce small runs below 300 pcs?

→ Yes, but the unit cost will be higher due to setup and sampling fees. GPLPAK offers flexible options for trial runs or prototype testing.

Q3: Does using eco-friendly materials increase cost?

→ Slightly, yes — but it adds long-term brand value. GPLPAK uses FSC-certified and recyclable materials upon request.

Q4: How long does it take to get samples?

→ Usually 7 – 10 days for design + sample production. Mass production ≈ 20 – 30 days after sample approval.

Q5: How can I reduce the cost?

→ Increase order quantity, simplify structure, limit finishing effects, or consult GPLPAK to optimize box design without sacrificing quality.

The cost of custom rigid paper boxes depends on design complexity, materials, and order size — but it always reflects your brand’s value.

Working with GPLPAK ensures that every dollar you invest delivers not only a premium box but a memorable unboxing experience for your customers.

At GPLPAK, we help global brands turn vision into reality through professional design, advanced production, and sustainable materials.

Get in touch today to receive a free quote or discuss your next packaging project.

🔗 Contact GPLPAK for a Free Quotation

Author :Suka

Suka is a Senior Packaging Specialist at GPLPAK. Passionate about innovative packaging solutions and sustainable practices, Suka is committed to helping brands shine through distinctive and effective packaging strategies. With deep expertise in design trends and industry insights, Suka provides actionable guidance to entrepreneurs, creatives, and business leaders, ensuring their packaging is not only visually appealing but also environmentally responsible. Suka excels at turning concepts into practical solutions that connect with consumers and elevate brand success.

email:[email protected]

whatsapp:+86 13723519895

Hot News

Hot News2025-05-27

2025-09-10

2025-07-28

2025-07-30

2025-08-03

2025-08-06