- Overview

- Recommended Products

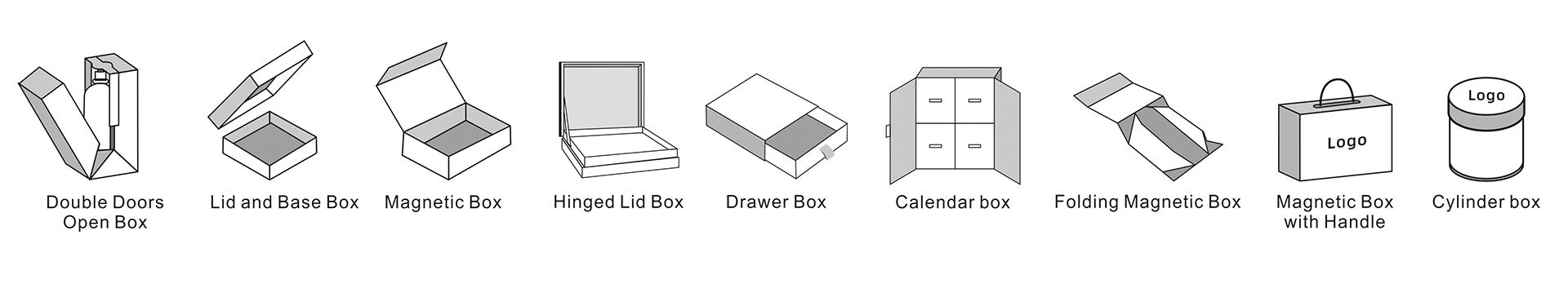

Dimension, style and structure: We encourage you to send your product dimensions (length, width, height), weight, fill-method and logistics packaging constraints; our in-house design team will propose the optimal rigid box type and layout.

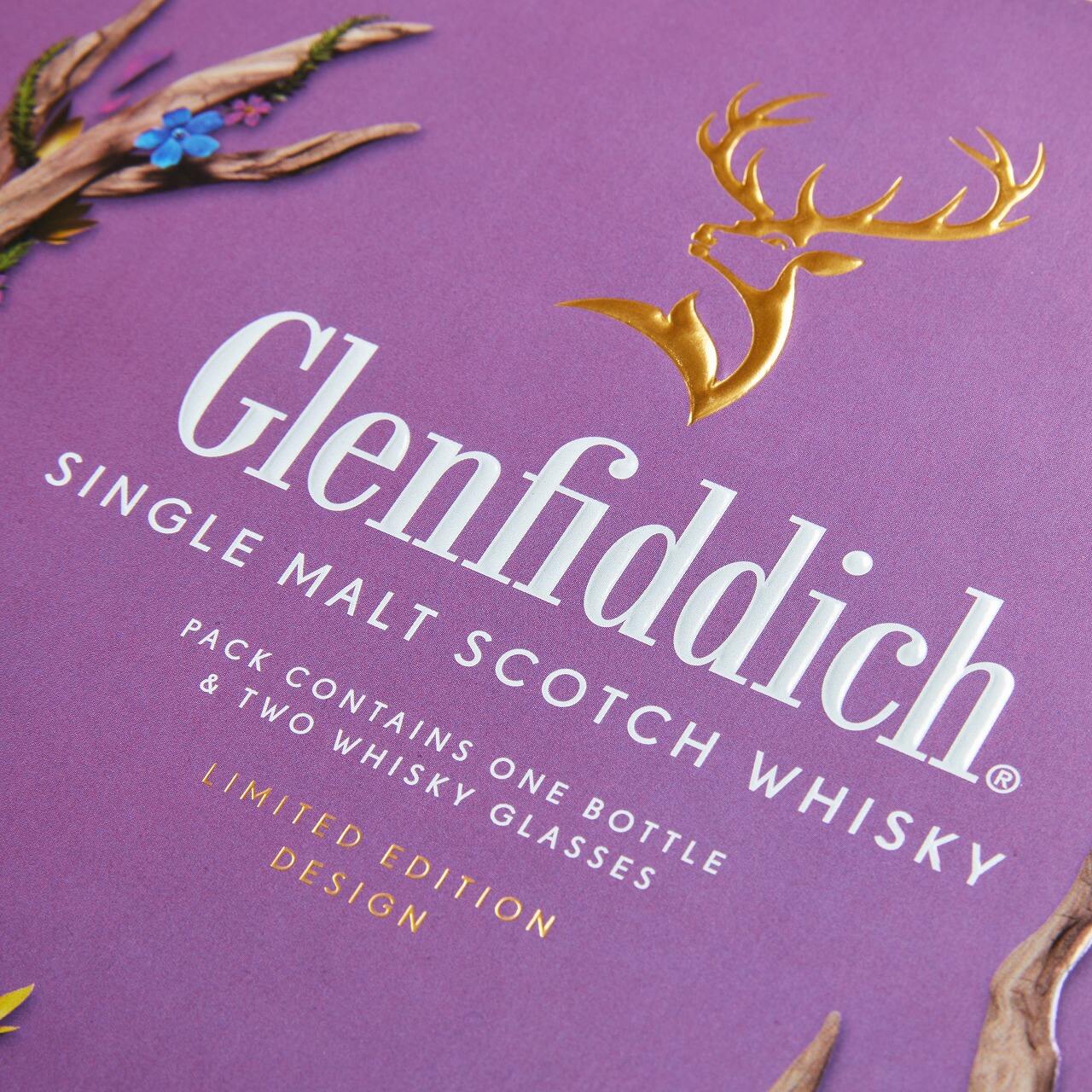

Branding & artwork: Submit your brand logo file (.AI or .EPS), specify foil size, position and colour; if needed, our team can generate dielines and 3D mock-ups for your approval.

Paper/textures and materials: Choose from standard art-paper, specialty textured paper, linen, leather-look paper, recycled boards. We provide sample swatches so you can confirm tactile and visual qualities.

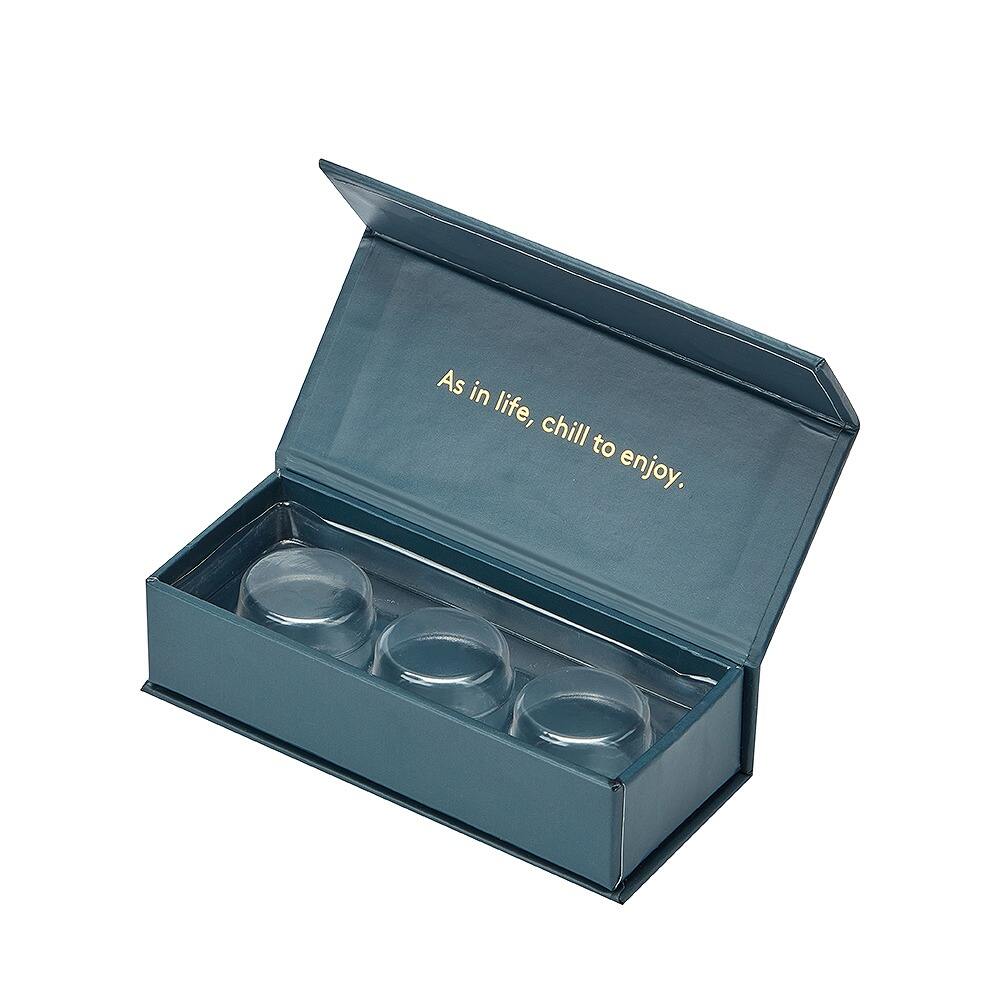

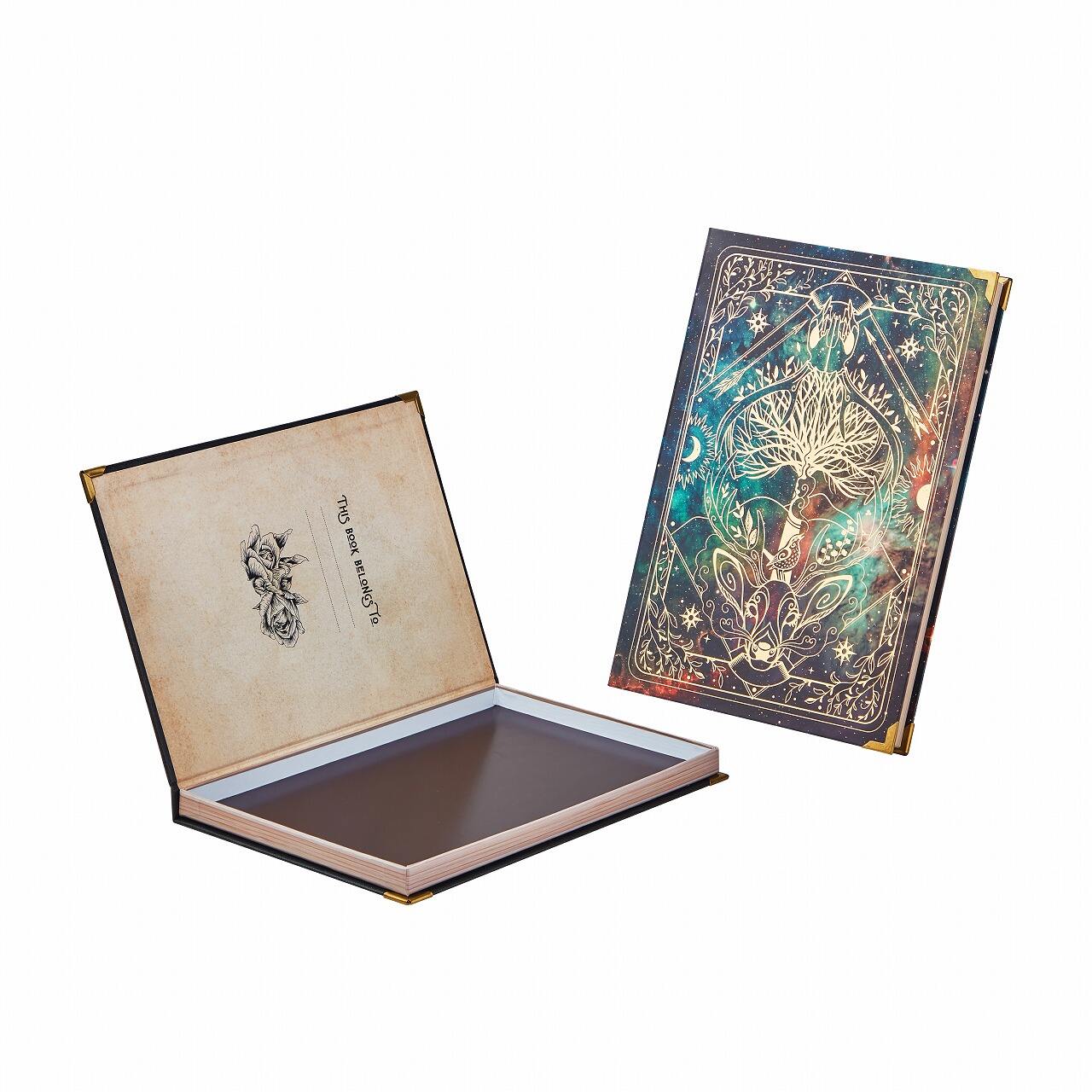

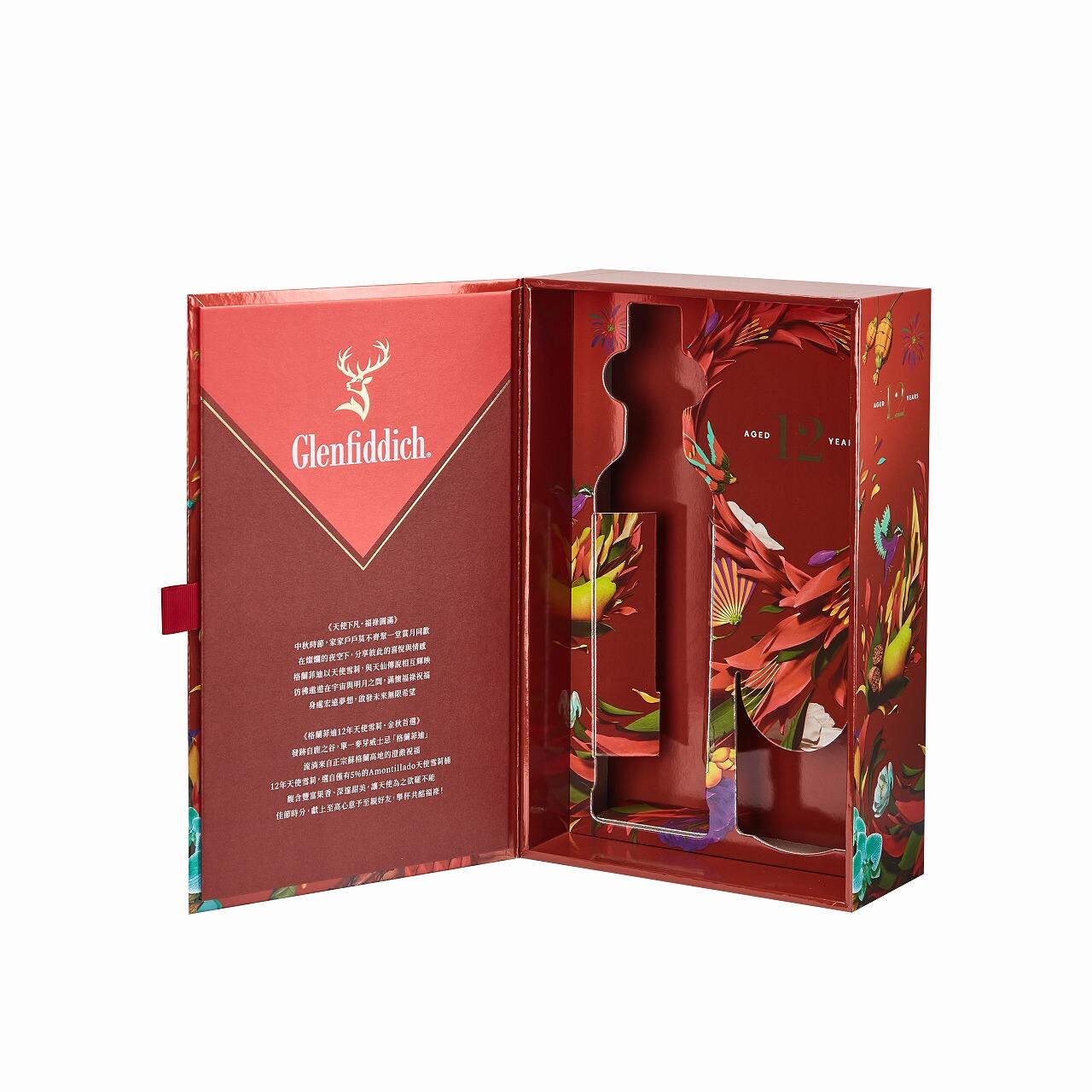

Inserts/trays: Based on your product components, we will design internal holders, cut-outs, foam or paperboard trays that maintain your items in place and present them attractively at unboxing.

Quantities & tooling: For first-time runs we recommend tooling up (e.g., for custom size, foil plate, inserts) which is one-time; thereafter for repeat orders the tooling cost is amortised. We support MOQ starting from mid-volume to high-volume runs.

Sustainability: If your brand emphasises eco-credentials, we offer FSC-certified board, water-based inks, and foil-free alternative options while still achieving premium appearance.

Prototyping & approval: After design sign-off, we supply a physical pre-production sample for your evaluation (structure, finish, foil appearance, assembly). Only upon your approval do we proceed to full production.

With heavy-gauge board and robust wrapping, your custom rigid box with gold foil logo ensures your product travels through transit, warehousing and retail handling with minimized risk of corner crush, deformation or damage. Studies show rigid-board packaging significantly reduces product damage and returns compared to standard cartons.

The “premium feel” of the box—its rigid walls, seamless wrap and metallic foil logo—creates a high perceived value at the moment the end consumer sees or holds it. For B2B buyers targeting luxury retail, gifting or limited-edition launches, this packaging becomes a tangible brand asset.

The unboxing moment is elevated: The foil logo, the tactile textured wrap, the custom insert and the rigid opening action combine to produce a memorable experience, creating brand recall and encouraging sharing (on social media) and repurchase.

Premium spirits and limited-edition whisky or cognac gift sets — the rigid box protects the bottle and accessories, while the foil logo reinforces luxury.

Jewellery or watch sets where durability, presentation and brand prestige matter most.

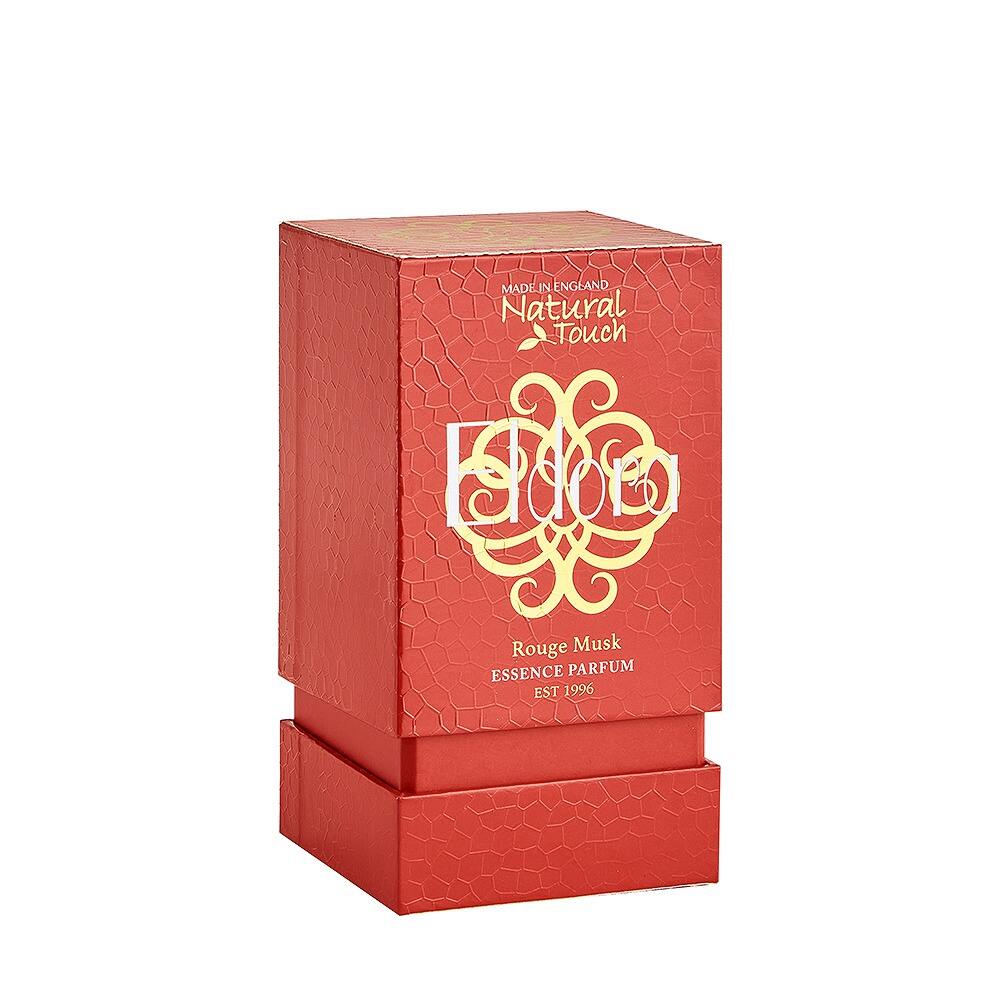

High-end cosmetics or fragrance collections packaged as gift kits — the box supports shelf display and gifting impression.

Corporate gifting, special-edition collaborations, promotional premium kits — where packaging plays a brand-story role beyond containment.

Subscription boxes in the luxury segment where customers expect premium tactile and visual quality upon opening.

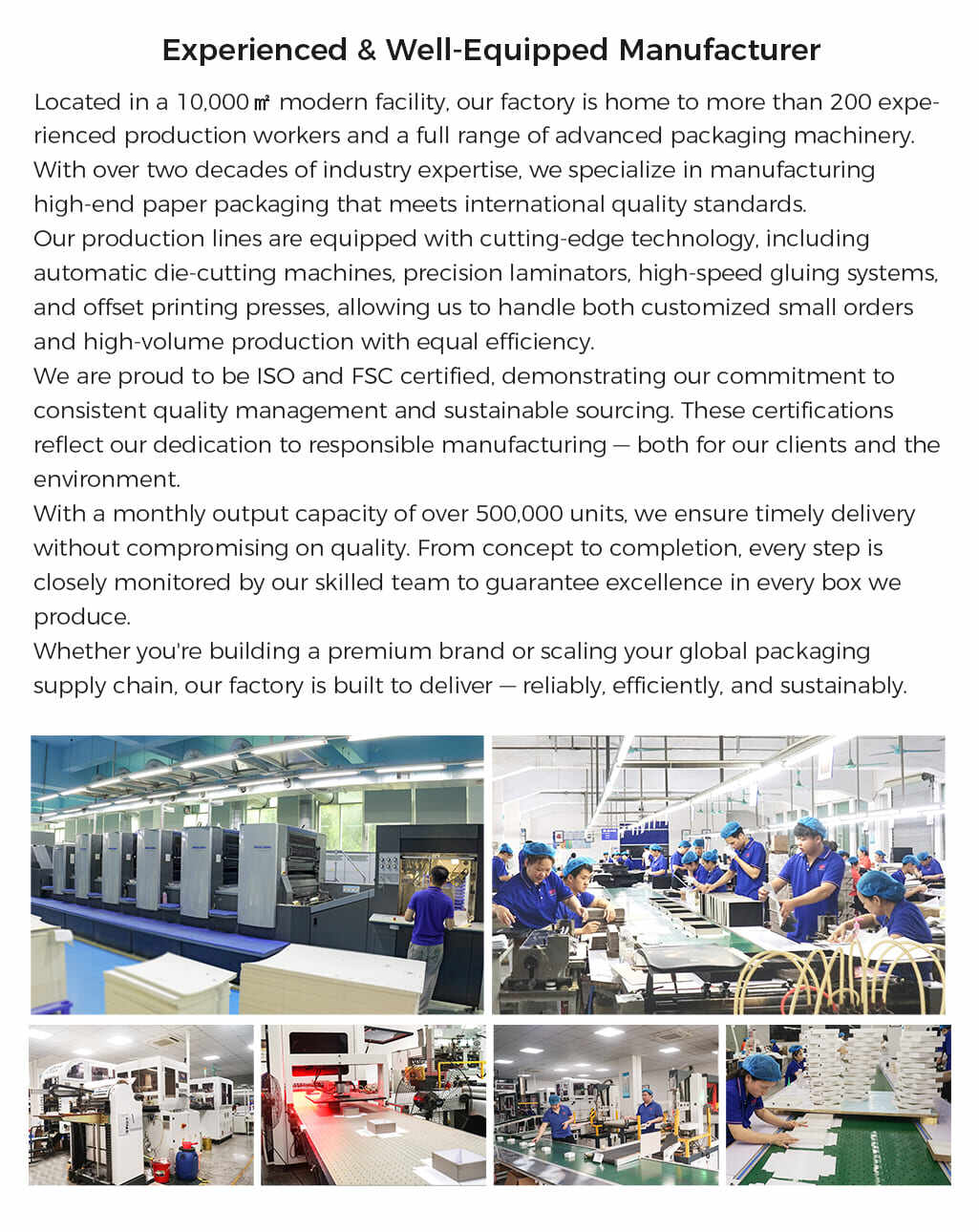

Over 10 years of specialised experience in manufacturing luxury packaging solutions for the European and North American markets; we understand finishing tolerances, export logistics and compliance.

Integrated design and manufacturing: From concept sketch, dieline design, material sourcing (specialty paper, foil), machine production, skilled hand-assembly (we employ a large team of experienced artisans) to final QA and global shipping.

Free sample support & digital mock-up: We provide physical sample for you to approve the feel, structure and foil quality before mass production.

Flexible OEM/ODM service: Whether you provide full artwork or need design support, we adapt and scale production to your needs, respecting MOQ, lead-time and quality standards.

Sustainable practices: We prioritise eco-friendly materials and finishing processes, helping your brand meet its sustainability commitments while maintaining luxury aesthetics.

Submit product dimensions, unit quantity, fill method, brand logo and preferred finish options (foil colour, paper texture, insert type).

We issue a quotation including tooling cost, unit cost, lead-time estimate and sample cost (if any).

Upon approval we send a 3D digital mock-up and/or physical prototype (typically lead time 7-14 days for prototype).

Once you sign off, we proceed to production (typical lead time 25–35 days depending on order volume and finishing complexity).

Final quality inspection, packaging, and shipment to your warehouse or nominated forwarder.

Repeat orders follow same quality control parameters; tooling already exists, so unit cost lowers with scale.

Product description

Premium Custom Rigid Box with Gold Foil Logo – Elevate Your Brand Packaging

When your brand demands packaging that mirrors the product’s excellence, our custom rigid box with gold foil logo delivers the perfect union of protection, presentation and prestige. Designed and manufactured by our factory in China (with over a decade of experience in high-end packaging for luxury markets), this rigid box solution is tailored for brands in spirits, jewellery, cosmetics, watches, gifting and premium retail.

Key Features and Benefits:

3. Customisation & Design Engagement

4. Protection & Brand Experience

5. Typical Applications & Ideal Use Cases

6. Why Choose Our Factory & Packaging Team

7. Ordering Workflow & Lead Times

8. Call to Action

Ready to upgrade your packaging and make every first touch count? Contact us today to start your custom rigid box with gold foil logo project. We’ll help you design, prototype and manufacture a packaging solution that wraps your product—and your brand story—in unmistakable quality and luxury.