производитель бумажных коробок

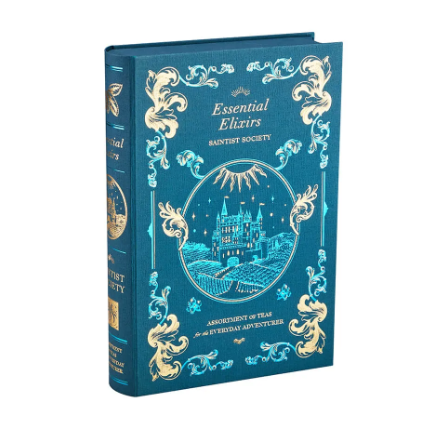

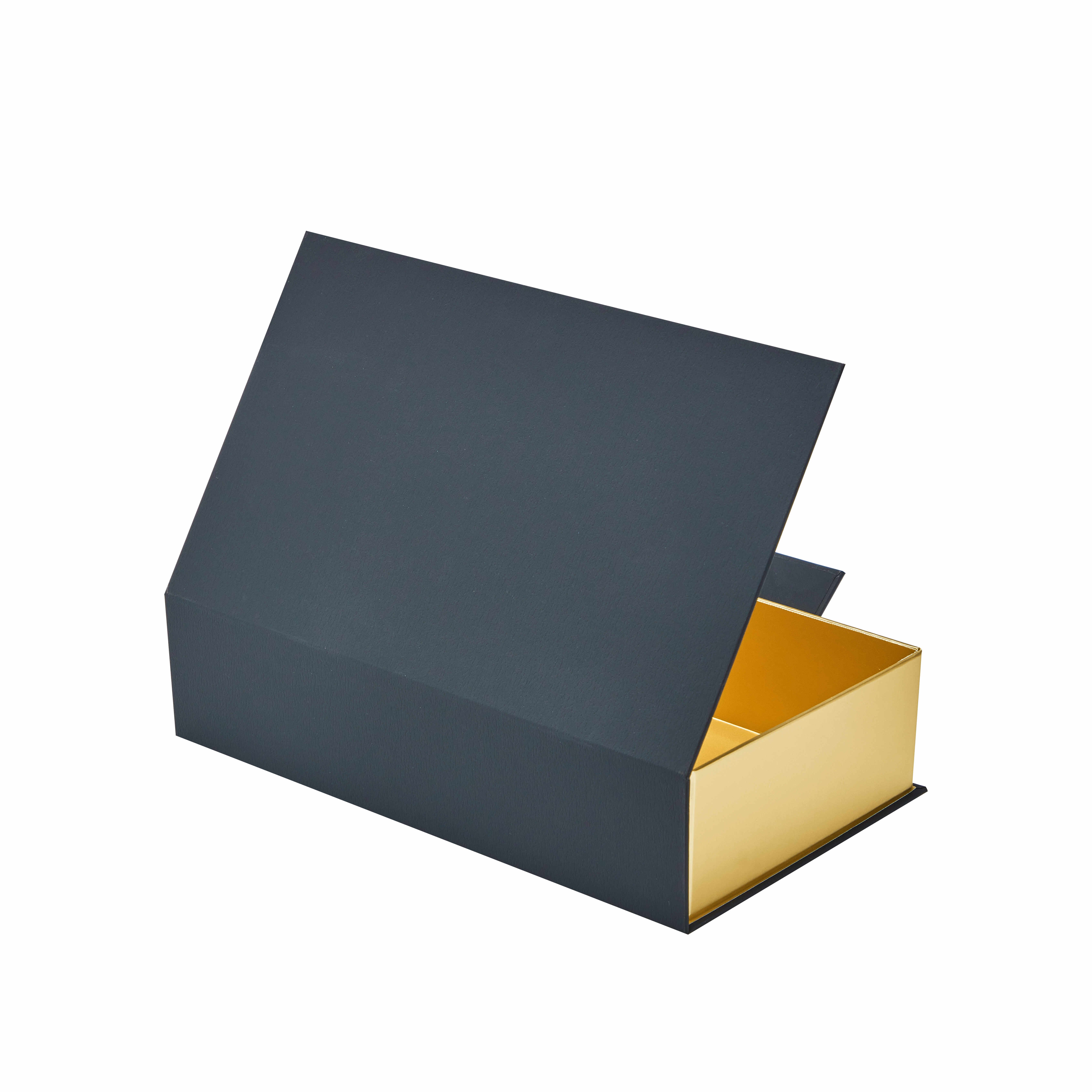

Производитель картонных коробок представляет собой сложную промышленную операцию, сочетающую передовые технологии производства с устойчивыми решениями упаковки. Эти предприятия используют современное оборудование и автоматизированные системы для преобразования сырьевых бумажных материалов в индивидуальные решения для упаковки. Процесс производства охватывает несколько этапов, включая разработку дизайна, вырубку, складывание, клейку и проверку качества. Современные производители картонных коробок используют системы компьютерного проектирования (CAD) для точных измерений и обеспечения структурной прочности, гарантируя, что каждая коробка соответствует точным спецификациям. Предприятия оснащены высокоскоростными производственными линиями, способными выпускать тысячи единиц продукции в час при поддержании постоянного качества. Продвинутые печатные возможности позволяют создавать графику высокого разрешения, цвета бренда и специальные финишные эффекты. Эти производители часто интегрируют устойчивые практики, используя переработанные материалы и внедряя стратегии снижения отходов. Гибкость их операций позволяет производить различные типы коробок, от простых почтовых до сложной розничной упаковки с особенными функциями, такими как окна, вставки или специальные застежки. Системы контроля качества, включая автоматизированную визуальную проверку и оборудование для тестирования прочности, обеспечивают соответствие каждого продукта стандартам отрасли и спецификациям заказчика.