In the world of luxury custom packaging, a “sample” is far more than just a pre-production proof — it’s a promise of quality and craftsmanship.

For companies like GPLPAK , a leading Chinese manufacturer specializing in premium paper rigid boxes for wine, cosmetics, jewelry, and watches, understanding the difference between digital samples and offset samples is essential.

Knowing which sample type to use at each stage helps brand owners make informed decisions, avoid costly mistakes, and ensure that every box perfectly represents their brand identity.

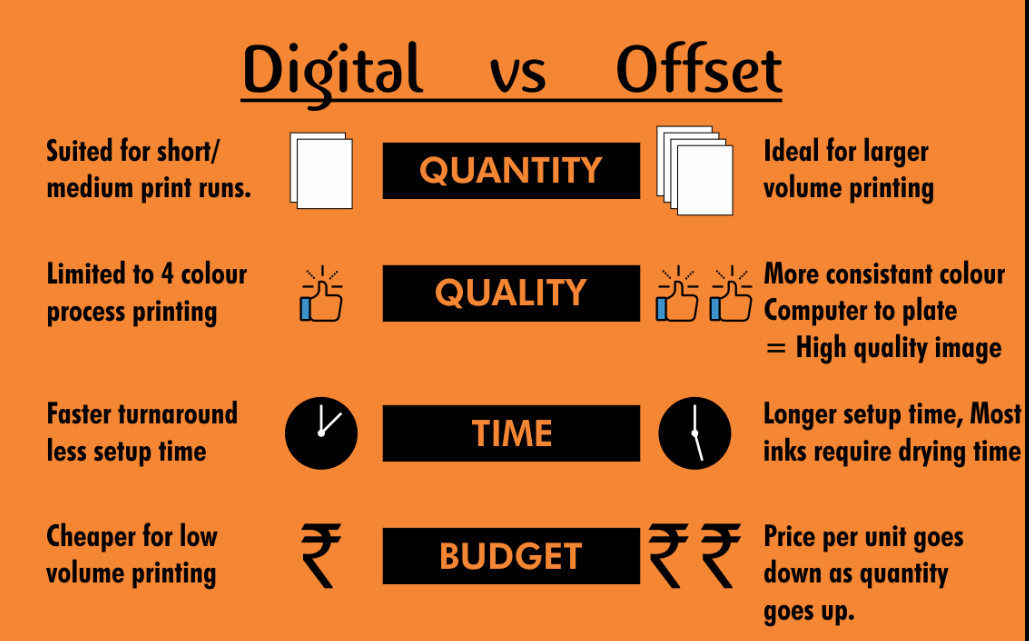

A digital sample is created using a digital printing machine, directly from a digital file without plate making.

It’s mainly used for concept approval, structure verification, and initial visual review.

Fast turnaround: No need for plate setup or large-scale preparation — ideal for design development or quick iterations.

Cost-effective: Suitable for small quantities or prototype testing.

Great for structure testing: Perfect for confirming box fit and design, especially for styles like lid-and-base boxes, drawer boxes, or heart-shaped gift boxes.

Ideal for customization: Excellent for limited editions or personalized packaging that changes frequently.

Lower color accuracy: Digital inks and substrates often differ from those used in mass production, resulting in slight color variation.

Limited post-print finishes: Complex effects like foil stamping, embossing, UV coating, or soft-touch lamination may not be achievable.

Not suitable for final approval: For luxury packaging projects with strict color and tactile expectations, digital samples alone are insufficient.

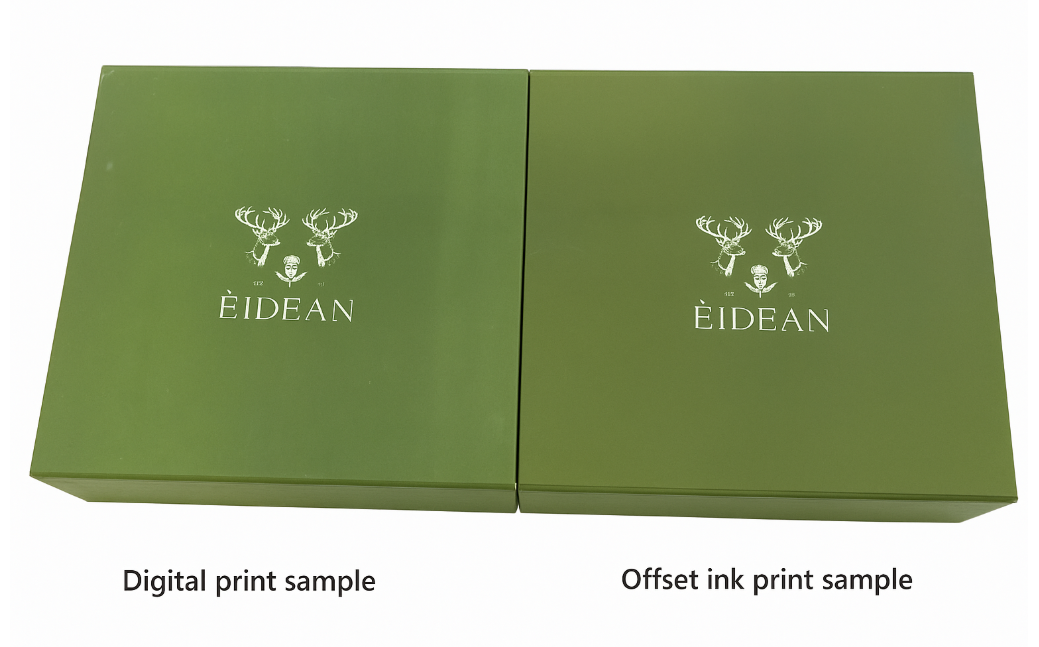

An offset sample is produced using the same or similar offset printing machines, inks, and paper as in mass production.

This means it provides a true-to-production representation of your final box — both visually and tactually.

Superior color accuracy: Uses Pantone or spot colors with the same materials and processes as full-scale production.

Supports luxury finishes: Includes hot stamping, embossing, UV coating, lamination, metallic foils, and other specialty effects.

Perfect for final approval: Especially suitable for luxury products like wine, perfume, and jewelry packaging.

Predicts production quality: Helps clients confirm the design before committing to mass production.

Longer lead time: Requires plate making, color matching, and setup.

Higher cost: Due to machine setup and prepress work.

Less flexibility: Each design change requires new plates, increasing time and cost.

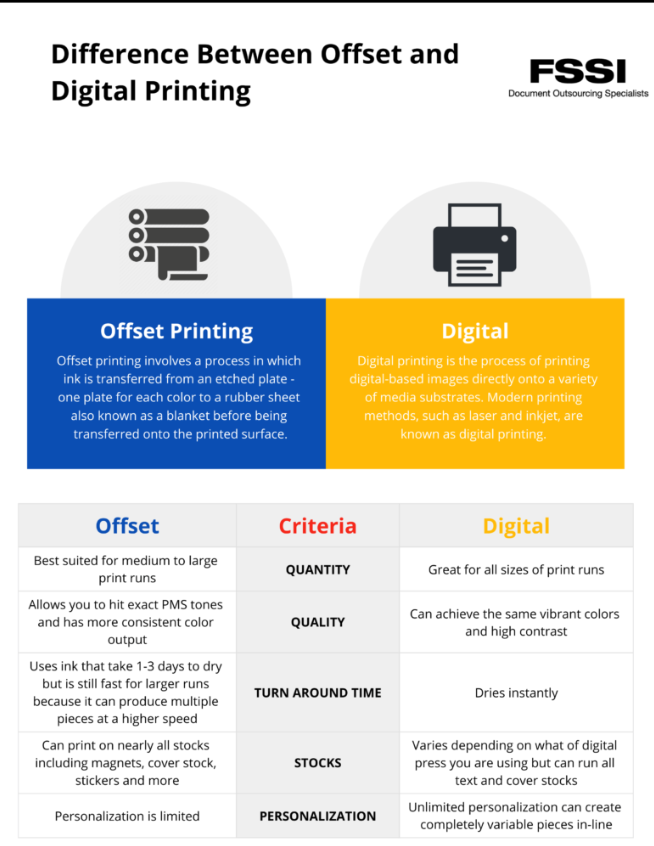

| Criteria | Digital Sample | Offset Sample |

|---|---|---|

| Preparation | Fast, no plate making | Slower, requires setup |

| Cost per piece | Lower | Higher (setup cost) |

| Color accuracy | Approximate | Excellent (spot/Pantone match) |

| Best for | Early design testing, small batches | Final approval, luxury packaging |

| Finishing options | Limited | Full luxury effects supported |

| Risk level | Higher – may differ from final | Lower – true pre-production result |

| Recommended stage | Concept / structure review | Final production confirmation |

As a custom luxury packaging manufacturer, GPLPAK provides both digital and offset sampling services to global clients.

When clients first request a new design (for example, a wine box or perfume box), digital sampling is ideal.

It allows fast feedback on structure, paper texture, and overall look — before investing in full production.

For projects involving gold foil stamping, silver embossing, or soft-touch coating, offset sampling is strongly recommended.

Packprince, with 20+ advanced machines, 200+ skilled workers, and a 10,000 m² facility, can reproduce precise brand colors and finishes that match final production.

Offset samples serve as a “production rehearsal.”

They give brand owners full confidence before bulk manufacturing begins — ensuring that color, texture, and finishing meet luxury brand standards.

For short-run or limited-edition packaging, a combination of both sampling methods can optimize speed and cost.

Start with digital sampling, then confirm with offset sampling before mass production.

Experience: Over a decade of expertise in luxury rigid box manufacturing for wine, cosmetics, and jewelry brands.

Expertise: End-to-end sampling and production — from design and digital proofing to offset printing and hand assembly.

Authority: Trusted by top brands including Dior, Sephora, Armani, Balenciaga, Glenfiddich, Dolce & Gabbana, and Moschino.

Trustworthiness: Offers eco-friendly materials, reliable logistics, and consistent after-sales support.

GPLPAK ’S one-stop service ensures that your digital and offset samples truly represent your brand before going into full-scale production.

Hot News

Hot News2025-05-27

2025-09-10

2025-07-28

2025-07-30

2025-08-03

2025-08-06