Why manufacturer selection matters

Packaging is not only a container—it’s a supply-chain system. The right manufacturer keeps your product safe, your branding consistent, and your replenishment predictable. The wrong choice creates hidden costs: rework, delays, inconsistent finishing, damage claims, or compliance issues.

Typical buyer pain points

- Samples look great, but production quality drifts.

- Lead times expand unexpectedly near peak season.

- Material/finish changes happen without approval.

- Export packing is weak—premium boxes arrive damaged.

- Slow communication causes repeated revisions.

What a strong partner delivers

- Documented specs + checkpoints for repeatable output.

- Realistic timelines and capacity planning.

- Materials and inserts engineered for protection.

- Pre-shipment inspection with acceptance criteria.

- Clear project ownership and fast feedback loops.

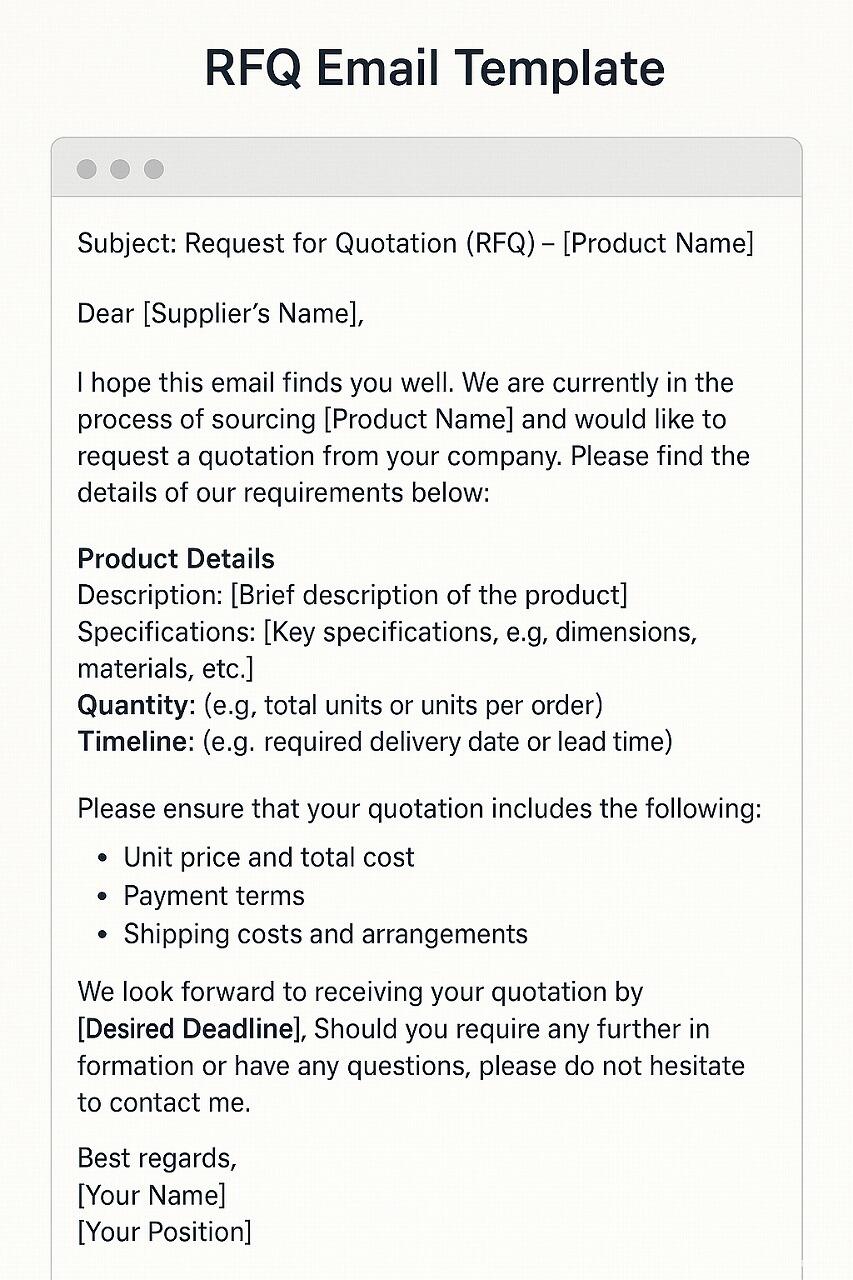

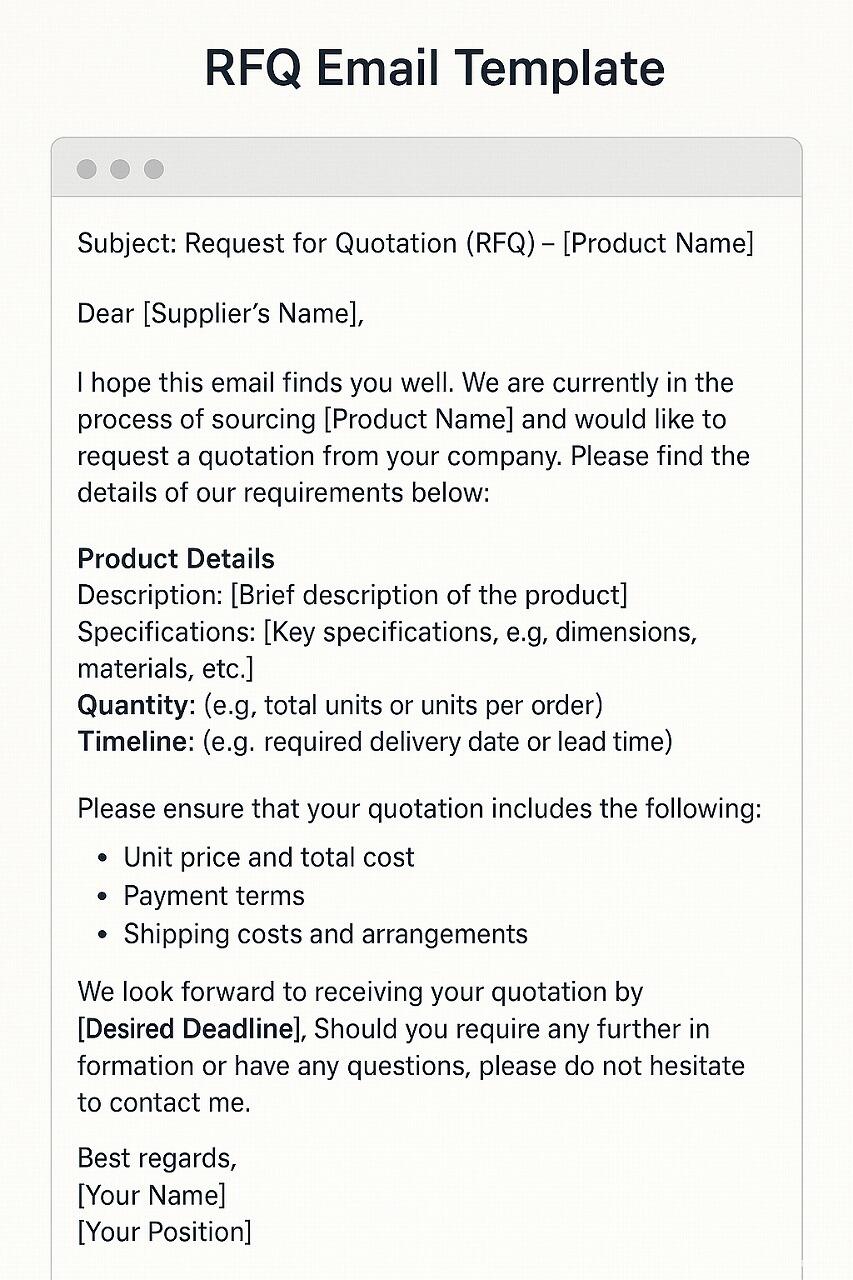

How to use this checklist

Copy the seven questions into your RFQ and ask suppliers to answer in writing—preferably with photos, process documents, and a clear timeline. Then score each supplier consistently (see scorecard section) to avoid choosing based on price alone.

Procurement shortcut: You are not buying “one good batch.” You are buying a repeatable system that can deliver the same results across multiple shipments.

The 7 key factors buyers should evaluate

Each factor includes a question you can directly copy into your RFQ, followed by what good answers look like and red flags to avoid.

1

Capabilities & fitWhat packaging structures and finishing capabilities can you produce in-house, and which steps are outsourced (if any)?

Strong answers include

- A clear in-house vs outsourced map (printing, lamination, foil, emboss, inserts, assembly, packing).

- Examples of similar structures/finishes and how they control tolerances.

- Engineering guidance—not just quoting what you send.

Red flags

- “We can do everything” with no process detail.

- No visibility into outsourced steps and who owns quality.

- Unable to advise on structure or insert design.

Why it matters: A supplier’s real capability determines consistency, risk, and whether your project can scale.

2

Quality system & repeatabilityWhat quality checkpoints do you use from sampling to mass production, and how do you keep results consistent across batches?

Strong answers include

- Incoming material checks, in-process controls, final inspection, and packing verification.

- Golden sample + pre-production approval method, with signed specs.

- Clear acceptance criteria and how issues are corrected.

Red flags

- “We inspect everything” without measurable standards.

- No defined approval process before mass production.

- Refusal to share inspection evidence.

Why it matters: Your biggest risk is production drift. You need documented controls, not only a nice sample.

3

Materials, inserts & protection engineeringWhich materials, coatings, and insert options do you recommend for my product, and what testing do you suggest (drop/compression/humidity)?

Strong answers include

- Material recommendations tied to performance (strength, scuff resistance, humidity tolerance).

- Insert proposals (paperboard, molded pulp, EVA/foam) based on fragility and finish.

- A practical test plan aligned to your channel (retail vs e-commerce vs export).

Red flags

- Only “standard” materials with no product reasoning.

- No mention of real transit stress or humidity.

- Protection treated as optional rather than engineered.

Why it matters: Damage and returns cost more than better materials. Protection should be designed, not guessed.

4

Lead time realism & capacity planningWhat is your typical lead time for each stage (sampling, approval, mass production, QC, packing), and what can cause delays in peak season?

Strong answers include

- Stage-by-stage timelines and dependencies (artwork, special finishes, sourcing).

- Capacity transparency and how they prioritize orders.

- Milestones and progress updates to prevent surprises.

Red flags

- Unrealistically short promises without detail.

- No milestones or progress reporting.

- Blaming only shipping while ignoring production constraints.

Why it matters: Launch dates and replenishment depend on lead time accuracy—not optimistic estimates.

5

Communication & project managementWho will manage my project daily, what is your response-time standard, and how do you handle revisions, approvals, and escalation?

Strong answers include

- A named project owner and a response-time promise.

- A structured workflow: dieline → artwork → sample → approval → production.

- An escalation method when quality or timing issues appear.

Red flags

- Too many contacts and unclear ownership.

- No approval checkpoints—changes get repeated.

- Slow or vague responses to technical questions.

Why it matters: Many delays are communication delays. Strong PM reduces revisions and protects schedules.

6

Sustainability & compliance readinessWhat sustainability options and compliance practices do you support (material sourcing, recyclability guidance, and documentation for audits)?

Strong answers include

- Eco options with tradeoffs explained (finish feel vs durability vs cost).

- Document habits for procurement audits and traceability.

- Design-for-recyclability guidance (reduce mixed materials, smart finish choices).

Red flags

- Green claims without substance or documentation.

- Eco options offered as a slogan, not engineered solutions.

- Unclear sourcing and inconsistent material records.

Why it matters: Sustainability is increasingly a procurement requirement. You need real options + proof.

7

Export packing & logistics protectionHow do you pack finished goods for export, what are your carton/pallet protections, and how do you reduce damage risk in international shipping?

Strong answers include

- Export packing standards (inner protection, carton strength, labeling, palletizing if needed).

- Finish protection (scuff prevention, corner guards, dust control).

- Pre-dispatch verification and photo evidence of packing.

Red flags

- No defined export packing method.

- Ignoring premium finish protection (foil/soft-touch scratch easily).

- No willingness to share packing photos/specs.

Why it matters: Export packing is part of quality. Even perfect production can fail at the shipping stage.

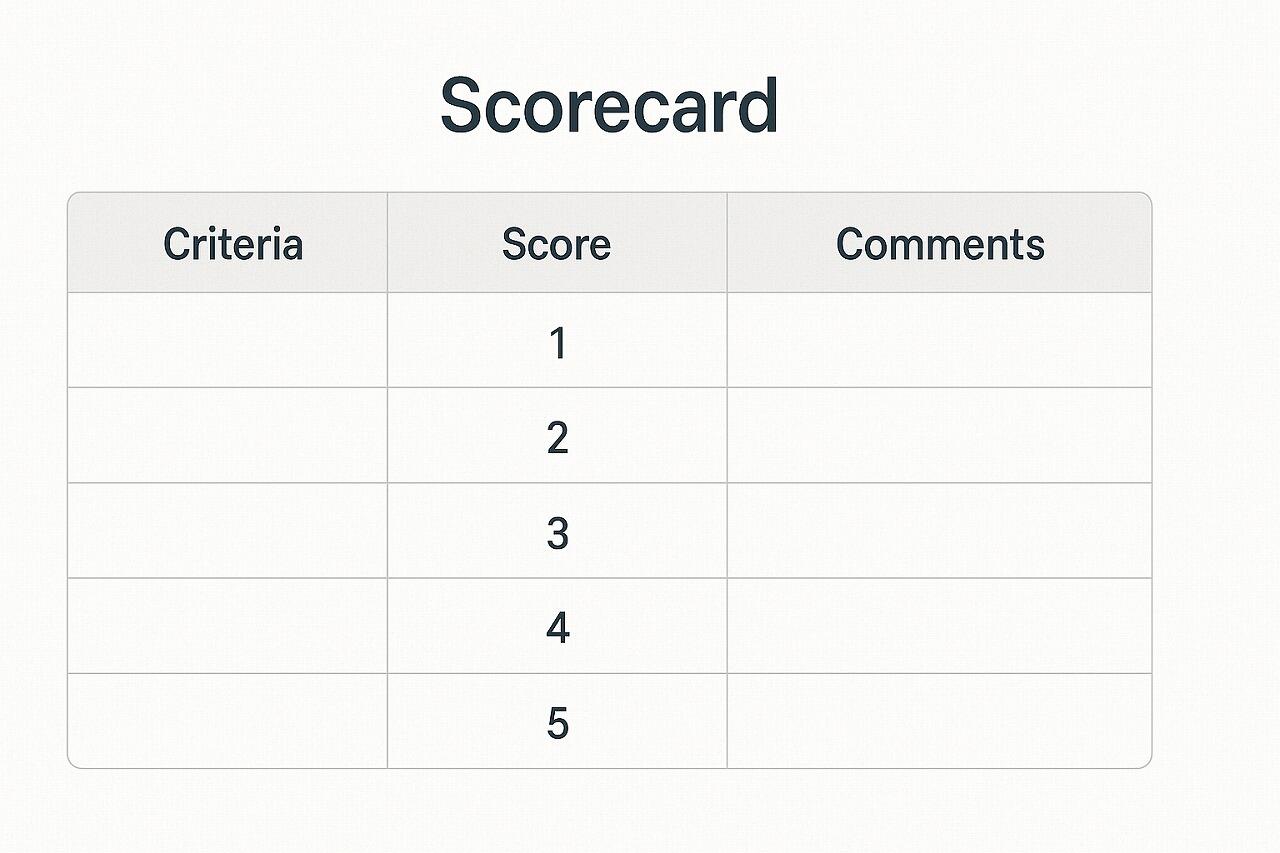

Simple supplier scorecard (fast comparison)

Once you collect answers from multiple suppliers, score each category 1–5. This highlights risk and prevents “lowest quote bias.”

Suggested scoring categories

- Capability fit (structures + finishes)

- Quality system & documentation

- Lead time reliability

- Materials & protection engineering

- Communication & project ownership

- Sustainability & audit readiness

- Export packing standards

How to reduce overseas risk

- Lock specs early (materials, thickness, paper, finish, tolerances).

- Approve a golden sample for finishing and color reference.

- Define acceptance criteria before mass production.

- Request inspection and packing evidence before shipment.

Why many brands choose GPLPAK

GPLPAK supports brands that need premium packaging with consistent execution—especially where structure, finishing, and shipping performance must work together. We focus on clear specifications, practical engineering, and production-ready support.

What we need to quote accurately

- Box type + size + target quantity

- Material/finish preference (or reference images)

- Insert requirement and protection goal

- Shipping destination + timeline

FAQ

How many suppliers should I compare?

Usually 3–5. Prioritize suppliers who can explain their system and show evidence, not only a low price.

What should I send for accurate quoting?

Dimensions, structure type, target material/finish, insert needs, quantity, destination, and channel (retail/e-commerce).

How do I protect premium finishes during shipping?

Ask about scuff protection, corner protection, carton strength, and packing verification photos before shipment.

How do I reduce production drift?

Use a golden sample, lock specs, define acceptance criteria, and require in-process and final inspection evidence.

Ready to evaluate your next packaging manufacturer?

If you want a supplier who can support premium presentation and production stability, GPLPAK can help you engineer the structure, materials, finishing, and export packing—then deliver consistently at scale.

Get a fast, professional quote from GPLPAKShare your box size, target quantity, reference style, and destination. We’ll reply with recommendations + timeline.

Hot News

Hot News