Cigarette Box Production Demystified: A Complete Guide to Materials, Compliance Standards, and Industrial Use

Cigarette packaging plays a critical role in the tobacco industry, serving not only as a protective cover for the product but also as a powerful tool for branding, consumer safety, and regulatory compliance. This guide provides a comprehensive overview of cigarette box production, covering materials, dimensions, compliance standards, and manufacturing techniques. We also highlight how GPLPAK excels in providing high-quality and customizable cigarette packaging solutions for brands around the world.

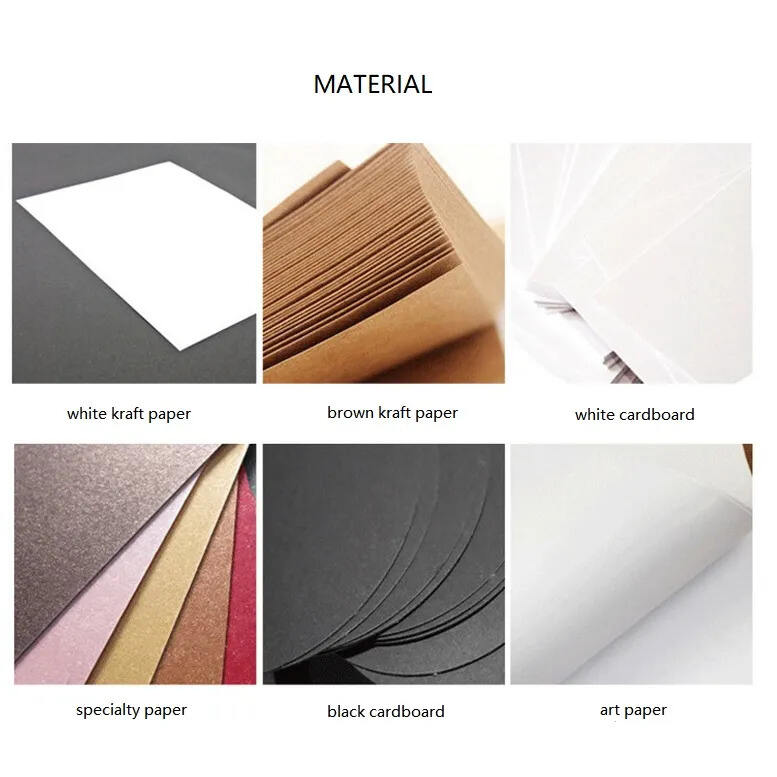

1. Materials in Cigarette Box Manufacturing

The materials chosen for cigarette packaging are fundamental in ensuring the quality, durability, and sustainability of the product. Here are the key materials used:

-

Paperboard: Paperboard is the most commonly used material in cigarette packaging. It offers great printability, a lightweight structure, and good durability. It is commonly used for standard cigarette packs, typically weighing around 300-400 gsm. Moreover, paperboard can be laminated for extra durability and protection.

-

Chipboard: Chipboard is thicker and more rigid than paperboard, offering more strength and a more premium feel. It’s used for luxury brands to ensure that the packaging has a sturdier structure and conveys high-end quality.

-

Plastic Films: Used mainly for tamper-evident packaging, plastic films are commonly applied as windows or seals. However, due to environmental concerns, the usage of plastic has been limited, with many manufacturers opting for recyclable materials.

-

Sustainability: Environmental sustainability is becoming a significant consideration in packaging. GPLPAK uses FSC-certified paperboard and other eco-friendly materials to meet growing demand for sustainable packaging solutions.

At GPLPAK, we ensure that all our packaging materials are sourced responsibly and meet both quality and sustainability standards.

2. Compliance Standards for Cigarette Packaging

Cigarette packaging is subject to stringent regulations that vary from country to country. These regulations are designed to protect public health, prevent youth access, and minimize environmental impact. The main compliance standards include:

-

Health Warnings: In many regions, cigarette packaging must carry graphic health warnings that occupy a significant portion of the pack, usually 65% or more of the front and back. These warnings often include pictures and text warnings about the dangers of smoking.

-

Child-Resistant Packaging: Some markets, including the US and Canada, require cigarette packs to be child-resistant. This prevents children from accessing tobacco products easily by incorporating secure packaging mechanisms.

-

Sustainability Regulations: With a growing focus on environmental protection, regulations now require that cigarette packaging be recyclable, biodegradable, or made from sustainable materials. The European Union’s Green Deal is a prime example of legislation pushing for higher recycling rates and reduced plastic use.

At GPLPAK, we design our packaging solutions to comply with these stringent health and environmental standards, ensuring your products can be sold in any market worldwide.

3. Cigarette Box Dimensions & the Cigaronne Style

The dimensions of a cigarette box are vital for both functionality and marketing. Standard cigarette packs typically measure around 85mm x 55mm x 22mm. However, many brands opt for different shapes and sizes to stand out, especially in premium markets.

One of the most popular custom box styles is the Cigaronne style box, which has gained popularity for its sleek, compact design. The typical dimensions for a Cigaronne-style box are 122mm x 65mm x 16mm, making it ideal for high-end products.

| Box Type |

Dimensions (mm) |

Usage |

| Standard Box |

85mm x 55mm x 22mm |

For regular 20-cigarette packs |

| Cigaronne Style Box |

122mm x 65mm x 16mm |

For luxury and premium brands |

| Slim Box |

85mm x 40mm x 20mm |

For slim cigarettes and niche markets |

At GPLPAK, we offer customized dimensions to suit any brand’s needs. The Cigaronne style box, for example, is designed to offer more space for branding while maintaining a sleek and modern aesthetic.

4. Key Production Techniques

Efficient cigarette box production relies on several key techniques to ensure precision, consistency, and high-quality output. These include:

-

Die-Cutting & Folding: Die-cutting creates the exact shape of the box, while folding ensures structural integrity. These techniques are essential for achieving precise, uniform boxes across large orders.

-

Printing Techniques: Offset printing is the most common method used in cigarette packaging, providing high-quality results. For premium finishes, UV coating and other printing techniques can be used to enhance the appearance and durability of the packaging.

-

Post-Production Finishing: Post-production processes such as embossing, foil stamping, and soft-touch lamination allow brands to create unique, premium designs that attract consumer attention.

GPLPAK uses cutting-edge, fully automated machines to ensure each cigarette box is produced with precision and speed, meeting high-volume demands without sacrificing quality.

5. The Cigaronne Style Box: A Trend in Premium Cigarette Packaging

The Cigaronne style box is a growing trend among luxury cigarette brands. It is a sleek, compact box that offers more space for intricate designs and branding elements. The box dimensions are 122mm x 65mm x 16mm, making it perfect for high-end products looking to stand out.

-

Why Cigaronne Style? The compact, elegant design and sturdy structure make it a popular choice for premium brands. Its larger surface area for branding allows brands to create a more memorable packaging experience.

-

Dimensions: The dimensions of the Cigaronne style box offer a perfect balance of compactness and elegance, making it ideal for luxury cigarette brands.

-

Unique Features: The Cigaronne style box allows for intricate branding elements and ensures the product stands out in the marketplace.

GPLPAK is known for its expertise in producing high-quality Cigaronne style boxes, and we offer a range of customization options to help our clients create a distinct packaging experience.

6. Industrial Production & Manufacturing at GPLPAK

At GPLPAK, we employ sixth-generation fully automated production systems to handle high-volume cigarette box orders. Our advanced systems provide:

-

High Production Capacity: Our automated systems can produce up to 50,000 units per day, ensuring fast fulfillment of large orders.

-

Quick Turnaround: We can deliver up to 100,000 sets within 30 days, ensuring that clients meet tight deadlines.

-

Quality Assurance: Every box goes through a strict quality control process to ensure that it meets all dimensional, aesthetic, and structural requirements.

Our automated machinery allows us to fulfill large-scale orders efficiently while maintaining consistent quality standards. At GPLPAK, we prioritize speed, precision, and sustainability in all our production processes.

7. How to Choose the Right Cigarette Box Manufacturer

When choosing a cigarette box manufacturer, consider the following key factors:

-

Experience: Choose a manufacturer with experience in the cigarette packaging industry to ensure they understand your needs.

-

Production Capacity: Ensure the manufacturer can handle your order volume and meet deadlines.

-

Customization: A good manufacturer should offer a wide range of design, material, and finishing options.

-

Compliance Knowledge: Make sure the manufacturer understands the regulatory standards in your region and can ensure compliance.

At GPLPAK, we have over 15 years of experience in the industry and are trusted by some of the largest tobacco brands for our quality, reliability, and customization options.

8. Frequently Asked Questions (FAQs)

-

What materials are best for cigarette boxes? – Paperboard, chipboard, and FSC-certified materials are the best options. These materials are durable, eco-friendly, and provide excellent printability.

-

How can I customize my cigarette packaging? – We offer a wide range of customization options, including size, shape, and finishes such as embossing, foil stamping, and soft-touch lamination. Contact us to learn more about the possibilities.

-

What are the lead times for large cigarette box orders? – Our production capacity allows us to deliver up to 100,000 sets within 30 days, ensuring quick turnaround times for large orders.

9. Conclusion

Cigarette packaging is an essential part of the tobacco industry. From selecting materials and ensuring compliance with regulations to choosing the right dimensions and manufacturing techniques, every detail matters. By partnering with GPLPAK, you gain access to high-quality, compliant, and customized cigarette packaging solutions that will elevate your brand.

Hot News

Hot News