Sushi push pop roll packaging represents a new generation of takeaway food packaging designed around convenience, hygiene, and brand experience. Unlike traditional sushi boxes, this cylindrical push-up structure changes how sushi is stored, transported, and consumed—making it especially attractive to premium sushi brands, takeaway chains, and retail-focused food businesses.

This guide is written specifically for B2B food packaging buyers. It explains the design logic behind sushi push pop roll packaging, explores material and food safety considerations, outlines customization possibilities, and clarifies manufacturing capacity requirements—based on practical production experience from GPLPAK.

Sushi push pop roll packaging is a cylindrical paper-based food container featuring a movable push-up base. By applying gentle pressure from the bottom, the sushi roll rises gradually from the top opening, allowing consumers to eat without directly touching the food.

This structure improves hygiene, reduces mess, and creates a more engaging eating experience. For takeaway and retail scenarios, it also helps maintain roll shape and topping integrity during transport.

The push pop sushi packaging concept gained rapid attention after a portable sushi design introduced by SUKA SUSHI went viral. The concept combines a cylindrical sushi container with a side-mounted, food-grade soy sauce tube, allowing consumers to enjoy sushi anywhere without carrying separate sauce cups.

From a buyer’s perspective, this design addresses multiple pain points at once: leakage control, ease of handling, portability, and visual differentiation. As a result, similar push pop formats are now being explored by sushi brands worldwide.

In competitive takeaway and retail markets, packaging has become a critical part of brand perception. Sushi push pop roll packaging stands out because it combines functional benefits with premium presentation.

A standard sushi push pop roll package is engineered for smooth movement, stability, and brand visibility. It typically consists of three integrated components:

Optional enhancements such as sauce tube holders, opening height adjustments, and reinforced wall structures can further improve performance for specific use cases.

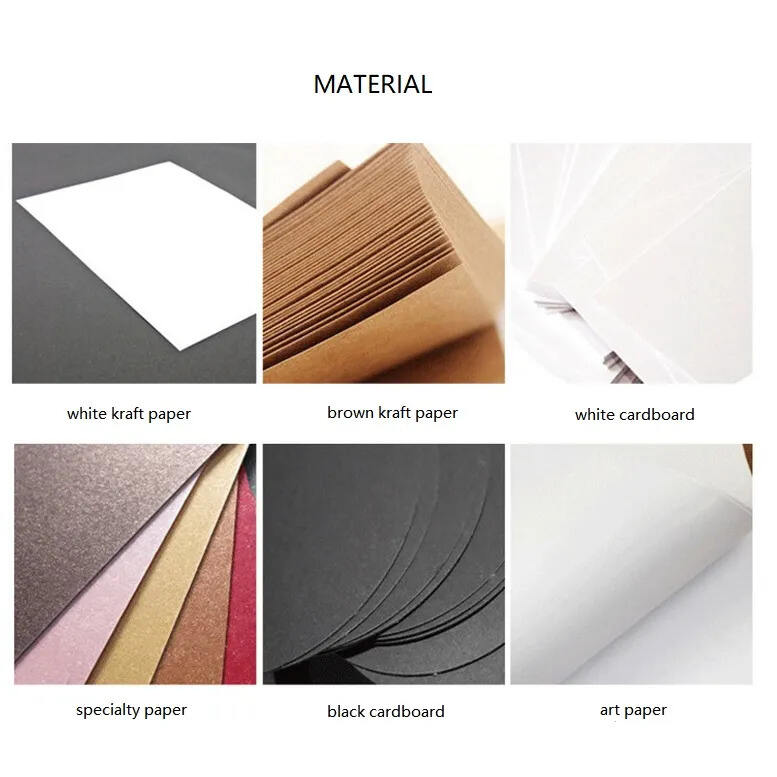

Food safety is non-negotiable for sushi packaging. At GPLPAK, sushi push pop roll packaging can be produced using certified food-grade paperboard and optional functional coatings tailored to your distribution environment.

For brands prioritizing sustainability, recyclable paper structures and eco-conscious coating options are available without compromising performance or appearance.

Customization transforms push pop sushi packaging into a strong branding tool. GPLPAK supports scalable customization suitable for both pilot projects and mass production.

Because GPLPAK already owns existing molds for this packaging structure, projects can move directly into sampling and production. This significantly shortens lead times while allowing you to create a design that fits your brand identity.

For B2B buyers, production capacity and delivery reliability are critical. GPLPAK is equipped to support both growing brands and large-scale sushi operations.

Learn more about our food packaging capabilities on our Custom Food Packaging page or contact our team directly via Contact Us.

Before placing a production order, food packaging buyers should evaluate the following factors:

Choosing a manufacturer with proven tooling, strong capacity, and food packaging experience reduces risk and accelerates time to market.

Whether you are developing a new sushi concept or upgrading takeaway packaging, GPLPAK offers fast customization, reliable capacity, and production-ready solutions.

Request a Quote to start your project.

Hot News

Hot News2025-05-27

2025-09-10

2025-07-28

2025-07-30

2025-08-03

2025-08-06