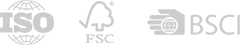

1. What Is a Calendar Paper Box & Why It Works for Holidays?

A calendar paper box is a multi-compartment rigid or folding box designed like a calendar. Instead of simply showing dates, each “day” opens up a small compartment containing a product: chocolate, minis, beauty samples, small gifts, or branded merchandise. For holiday campaigns, this concept is especially powerful because it combines:

- Storytelling – every day reveals a new part of your brand story or product line.

- High perceived value – customers get multiple items and a keepsake box they can reuse.

- Social-media friendly unboxing – ideal for influencers and user-generated content.

- Brand recall – the box stays on the desk or shelf for weeks, keeping your logo visible.

GPLPAK has developed various holiday calendar and advent solutions, including rigid advent boxes for chocolate and calendar-style magnetic folding rigid boxes that fold flat for efficient shipping.

2. Defining Your Holiday Campaign & Calendar Concept

Before you choose materials or structures, clarify what you want your calendar paper box to achieve. This will guide every technical decision.

2.1 Clarify your objectives

- Product launch – showcase a full range of SKUs over 12 or 24 days.

- Brand awareness – create a memorable branded gift for key accounts.

- Upsell & cross-sell – combine bestsellers with trial-size products.

- Corporate gifting – send calendar boxes to VIP clients and partners.

For example, GPLPAK often produces calendar boxes for chocolate, cosmetics, fragrance minis and mixed gift sets that run across a full holiday season.

2.2 Define the content & user experience

- Number of days/doors (12, 24, 25, or custom).

- Product types: food, skincare, fragrance, accessories, or mixed.

- Expected unboxing route: random doors or guided daily sequence.

- Key messages and storytelling for the inside printing.

Share these details with GPLPAK’s packaging consultation team so our engineers can recommend the most efficient structure and insert layout for your holiday calendar.

At this stage, many brands also browse our chocolate packaging collection and rigid box structures to get inspiration for shapes, closures and finishing styles.

3. Choosing the Right Structure for Your Calendar Paper Box

The structure determines not only the visual effect, but also logistics costs and end-user convenience. GPLPAK offers multiple structures that can be customized to your calendar concept:

3.1 Rigid advent calendar box

A premium choice for high-end chocolates, skincare sets, or gift assortments. Built from thick rigid board with individual cavities or drawers for each day.

- Strong, long-lasting keepsake box.

- Ideal for luxury brands and limited editions.

- Compatible with advanced finishes: foil stamping, embossing, spot UV.

GPLPAK’s FDA approved chocolate calendar box is a typical example of a rigid holiday calendar suitable for food-grade requirements.

3.2 Magnetic folding calendar paper box

A calendar-style magnetic folding rigid box combines a luxury look with fold-flat functionality:

- Ships flat to reduce freight and warehouse space.

- Assembled easily at the fulfillment center.

- Can be designed as a book-style opening with internal calendar trays.

If your campaign involves international shipping or e-commerce, this structure helps control total landed cost while keeping a premium brand image.

3.3 Drawer, book-style & door-opening calendar designs

Beyond classic “punch-door” designs, GPLPAK can engineer calendar paper boxes with:

- Drawer style – individual or grouped drawers sliding from the side or bottom.

- Book-style opening – a rigid “book cover” that opens to reveal inner calendar blocks.

- Double-door style – two doors opening from the center, with the calendar tray inside.

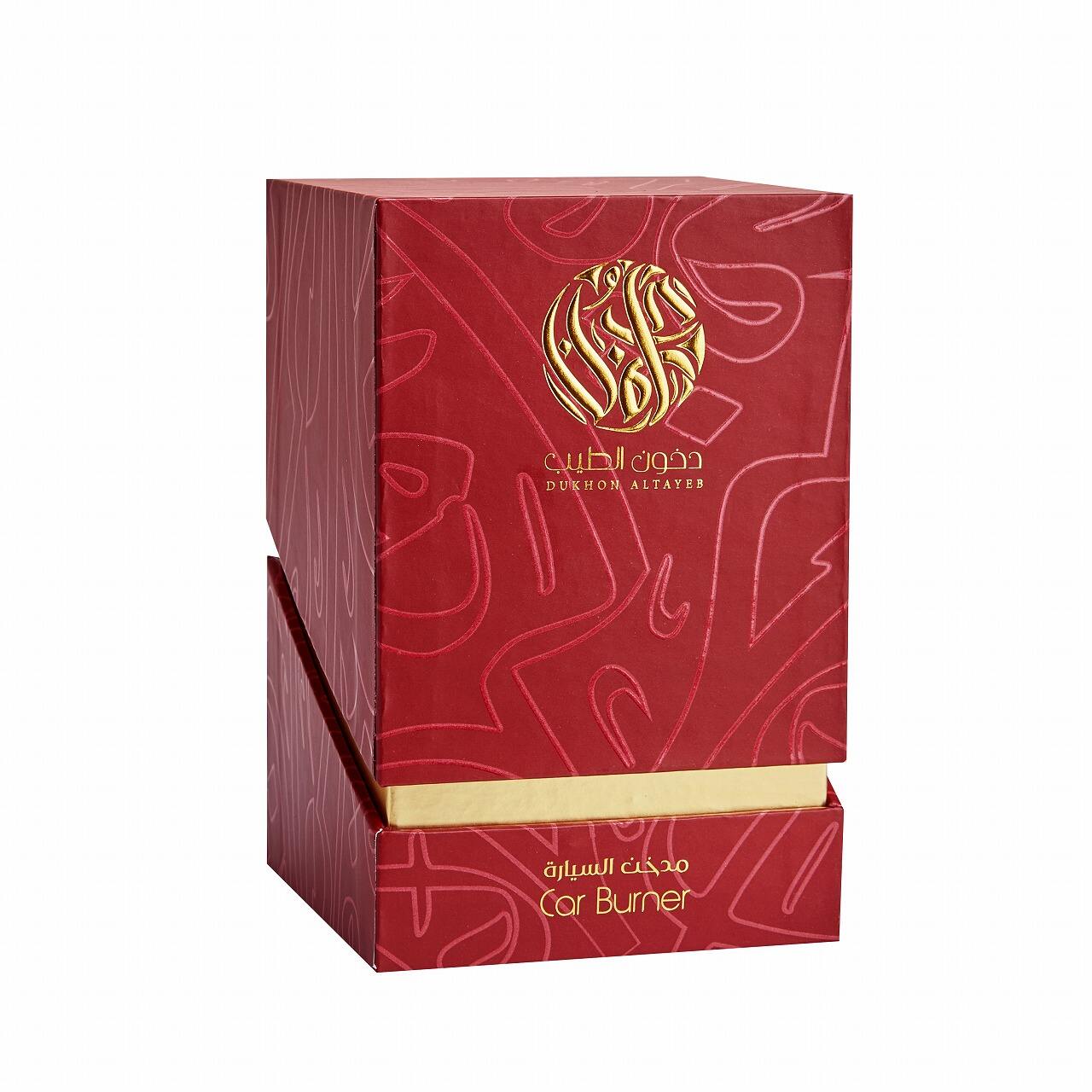

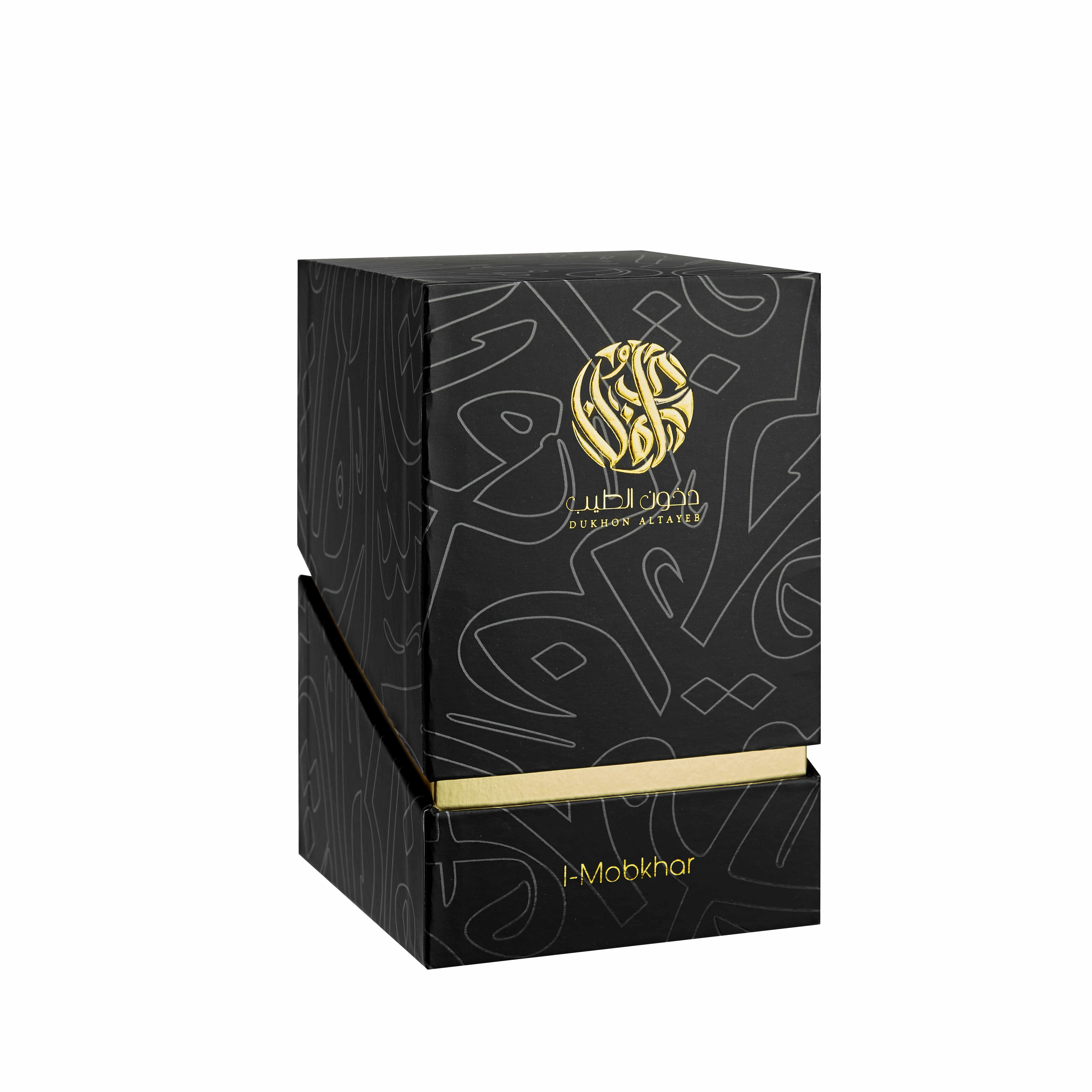

4. Material, Printing & Finishing Options

A holiday calendar paper box must be strong enough to hold multiple items while still looking refined. GPLPAK combines structural engineering with fine printing and finishing to achieve this balance.

4.1 Core materials

- Rigid greyboard (1.5–2.5 mm) – preferred for luxury advent calendars, offering excellent durability and shape stability.

- Art paper / coated paper (128–200 gsm) – for high-resolution CMYK printing, gradients and illustration-heavy holiday artwork.

- Specialty texture paper – linen, soft-touch, or metallic papers for a more tactile and premium feel.

- Corrugated board – for outer shipping boxes that protect the calendar box during long-distance transport.

Many of these materials can be explored across our structure-based product categories and corrugated shipping solutions.

4.2 Printing methods

- Offset CMYK printing – for detailed holiday illustrations and brand patterns.

- Pantone spot colors – to match your brand palette exactly.

- Inside printing – messages, numbers, mini stories or QR codes behind each door.

4.3 Finishing & decoration

The finishing layer often defines the “wow” factor of your calendar paper box:

- Matte or gloss lamination for protection and a clean surface feel.

- Soft-touch coating for a velvety, high-end touch.

- Hot foil stamping in gold, silver, or colored foil for logos and numbers.

- Embossing / debossing to highlight your brand name or holiday motif.

- Spot UV to make selected details shine under light.

To better understand how we manage premium surface finishing on rigid boxes, you can also review content like our packaging knowledge articles in the GPLPAK blog, such as guides for cosmetic and essential oil packaging.

5. Inserts & Internal Layout Design

A calendar paper box is only successful if each product is held securely in place. Well-designed inserts protect the contents, streamline packing, and create a clean unboxing experience.

5.1 Common insert materials

- EVA foam – precision-cut cavities, ideal for cosmetics and gifts.

- Sponge foam – softer feel for lightweight accessories.

- Cardboard / paperboard inserts – sustainable, cost-effective and recyclable.

- Molded pulp – eco-friendly protection for heavier products.

For food items like chocolate, inserts can be combined with food-grade trays or blisters to meet compliance requirements.

5.2 Layout considerations

- Align cavity sizes with product dimensions and tolerances.

- Group similar items across rows or weeks for storytelling.

- Plan for easy packing at your fulfillment center.

- Allow space for desiccant packs or safety leaflets if needed.

GPLPAK’s engineering team uses your product dimensions to draft a precise cavity layout and can provide white samples or printed prototypes before mass production.

6. Sustainability & Food-Grade Considerations

Modern B2B buyers expect holiday packaging to be both premium and responsible. GPLPAK supports this by offering sustainable materials and food-grade solutions where required.

6.1 Eco-friendly options

- Recycled or FSC-oriented paperboard for the outer shell.

- Water-based or soy-based inks for printing.

- Paper or cardboard inserts instead of purely plastic trays.

- Designs optimized to reduce material waste and improve pallet loading.

6.2 Food-grade calendar boxes

If your calendar paper box is used for chocolate, candies, or other edible items, we can combine:

- Food-contact compliant linings or blisters.

- Separate inner food trays placed inside the rigid calendar box.

- Clear labelling space for ingredients, shelf life and compliance marks.

For more references, you can review our dedicated chocolate packaging category and food-related calendar concepts.

7. Step-by-Step: How GPLPAK Customizes Your Calendar Paper Box

As a professional custom luxury packaging manufacturer, GPLPAK provides end-to-end support from concept to delivery. A typical holiday calendar paper box project follows these steps:

-

Consultation & briefing

You share your brand guidelines, calendar concept, product list, target quantity, and timing via the Contact Us / Get a Quote page. -

Structure & artwork proposal

GPLPAK’s packaging specialists recommend a suitable structure (rigid or magnetic folding), insert type, and external dimensions. We provide dielines so your designers can place artwork. -

Sampling & testing

A white sample or printed sample is produced for checking structure, print, color and overall user experience. Adjustments are made before confirming mass production. -

Mass production & quality control

Once approved, production runs in our 10,000 m² factory with 200+ skilled workers, where each calendar paper box is monitored under standardized QC procedures. -

Packing & logistics

Finished calendar paper boxes are packed (flat or assembled, depending on structure) and prepared for export. Our team can advise on carton and pallet loading to optimize freight cost.

Throughout the process, you can also draw on expertise from other GPLPAK projects, such as cosmetic, fragrance, and gift box solutions that share similar structures and finishing requirements.

8. Why Work with GPLPAK for Holiday Calendar Packaging?

When you custom a calendar paper box for holidays, you need a manufacturer who can manage both creative complexity and industrial reliability. GPLPAK combines both capabilities in one place.

8.1 Proven factory capabilities

- 10,000 m² production area with advanced printing and finishing equipment.

- 200+ experienced workers focused on rigid boxes and luxury packaging.

- OEM & ODM services for global brands across Europe, North America & beyond.

- Support for small to large order quantities, depending on your campaign scale.

8.2 Design, engineering & service

- Packaging consultation and product development support.

- Engineering for fold-flat and multi-compartment structures.

- Surface finishing expertise: foil, embossing, spot UV, soft-touch.

- Transparent communication and clear lead-time planning.

Many of these strengths are also reflected in other GPLPAK packaging knowledge articles and success cases, giving you confidence that your calendar project is backed by real manufacturing experience.

9. FAQ: Custom Calendar Paper Box for Holidays

Q1. What is the usual MOQ for a custom calendar paper box?

The minimum order quantity depends on the structure and finishing, but holiday calendar projects typically start from around a few hundred to a few thousand pieces. For an accurate MOQ and pricing reference, share your specifications (size, inserts, finishes, quantity) via the quote form.

Q2. How long does it take to develop and produce a calendar paper box?

As a guideline, allow time for 3 phases:

- Concept & dieline confirmation – typically 5–10 days.

- Sampling – usually 7–15 days depending on complexity.

- Mass production – often 25–40 days after sample approval.

To meet a specific holiday launch date, we recommend starting discussions with GPLPAK at least 3–4 months in advance, especially for international shipping.

Q3. Can my calendar paper box be food-grade for chocolate or candy?

Yes. GPLPAK can combine rigid calendar structures with food-grade inner trays, blisters or liners suitable for chocolate, candy and other confectionery. The outer calendar box can still use luxury finishes such as foil stamping and embossing while respecting food-contact requirements inside.

Q4. Do you provide design support for artwork?

You may use your own design team or work with GPLPAK’s creative support. We can provide dielines, structural recommendations, and practical guidance on how to place logos, numbers, and storytelling inside each door for the best printing results. If needed, we can assist with layout and pre-press checks.

Q5. Can GPLPAK help with matching other packaging in my brand line?

Yes. Many brands use calendar paper boxes alongside cosmetic, fragrance or standard gift boxes. GPLPAK can align paper types, colors and finishing with your existing cosmetic packaging, fragrance boxes or chocolate packaging to ensure a consistent brand image across all product lines.

10. Start Your Holiday Calendar Paper Box Project with GPLPAK

A well-designed calendar paper box is more than a seasonal gift. It is a powerful marketing tool that connects with your customers day after day throughout the holiday period. By combining structural innovation, premium materials and thoughtful storytelling, you can turn a single campaign into a memorable brand experience.

Ready to custom your next holiday calendar paper box?

Share your idea, campaign timeline and product list with GPLPAK, and our team will guide you from the first concept sketch to a finished calendar box ready for shelves, gifting, or e-commerce shipping.

Hot News

Hot News