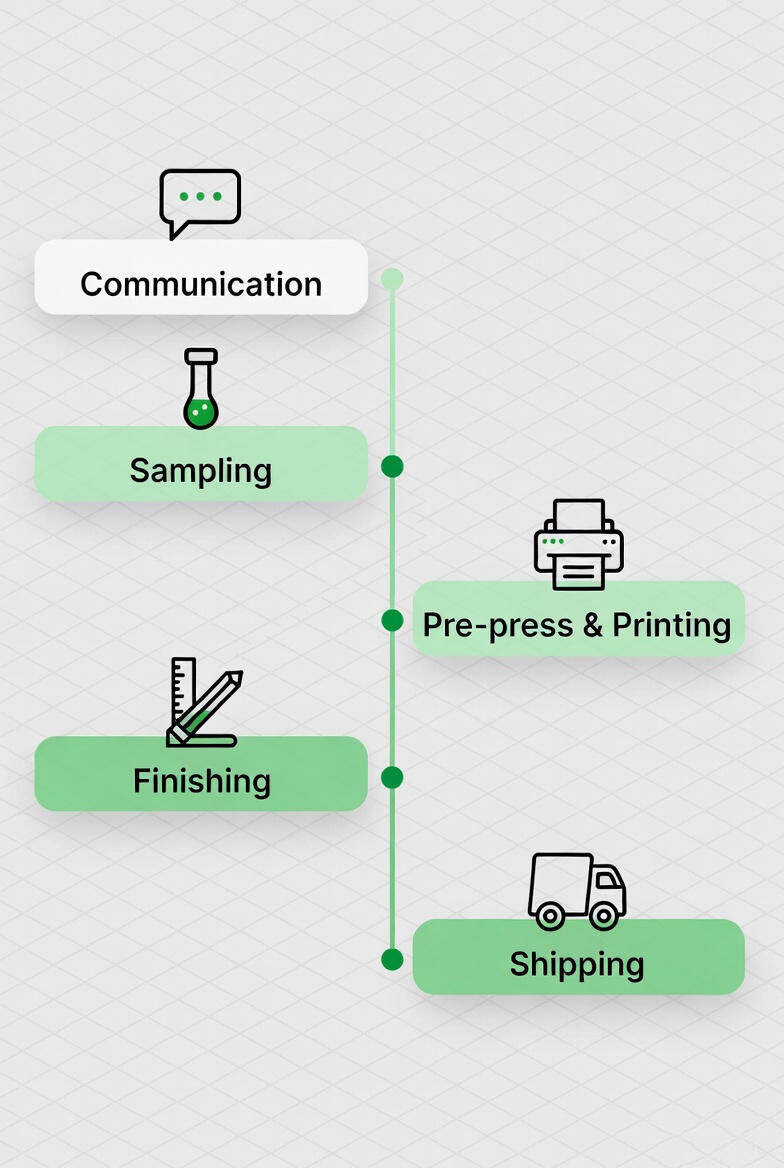

1. Snapshot: the full timeline from idea to delivery

Every project is slightly different, but most custom packaging orders produced in Asia follow the same big-picture timeline. The breakdown below assumes you are working with an experienced export factory such as GPLPAK and already have a clear product roadmap.

30–70 calendar days depending on product complexity, order quantity, and chosen shipping method.

2. Why lead time for custom packaging in Asia matters so much

For global brands, packaging is rarely just “the last step”. Late packaging often means delayed launches, missed seasonal windows, higher air freight costs, and unnecessary stress on marketing and sales teams.

Realistic lead time planning helps you:

- Align packaging delivery with product production and artwork deadlines.

- Reserve more economical shipping methods instead of last-minute air freight.

- Manage stakeholder expectations across marketing, e-commerce and retail buyers.

- Plan regional launches and replenishments without stock-outs.

- Build contingency buffers for holidays and unexpected disruptions.

At GPLPAK, we design every project timeline backwards from your target in-store or online launch date, then calibrate each production step to match that goal.

3. Stage 1 – Communication & project brief (2–5 business days)

The first stage is all about clarity. A well-defined brief can easily save a week of back-and-forth later in the project. For Asian factories that serve global brands, this step typically includes:

- Understanding your product, sales channel and target customer.

- Confirming box structure (rigid, folding carton, corrugated mailer, drawer, tube, etc.).

- Discussing quantity, budget range and required certifications.

- Agreeing on Incoterms (EXW, FOB, CIF, DAP) and preferred ports/airports.

- Reviewing your desired launch date and working backwards to a realistic schedule.

The better your inputs, the faster this stage moves. Brands who already know whether they need rigid gift boxes, corrugated shipping boxes or folding cartons usually progress faster and receive a more accurate quote on the first round.

How GPLPAK speeds up Stage 1

We use structured questionnaires, 2D/3D size guides and past case studies to clarify your requirements in one or two working days for most projects.

Talk to a GPLPAK project engineer↗4. Stage 2 – Design, engineering & sampling (5–15 business days)

Once the brief is clear, the next stage transforms your idea into a manufacturable packaging solution. This step has the biggest impact on lead time if artwork is not final or structural decisions keep changing.

Typical time allocation for this stage:

- Structural design & dieline creation: 2–5 business days.

- Digital artwork proofing: 1–2 business days per revision round.

-

Physical samples:

- White / blank sample (to confirm size & structure): 3–5 business days.

- Full printed pre-production sample: 5–10 business days (depending on finishes).

For complex projects – for example a luxury rigid box with hot foil, embossing, soft-touch lamination and drawer-style structures – we strongly recommend approving a full printed pre-production sample before mass production.

Tip: You can shorten this stage significantly when repeating an existing order with GPLPAK. We re-use stored tooling and dielines, only updating artwork or minor details, which often eliminates the need for a new sample.

To understand how GPLPAK approaches development, you can explore our Development Sampling and Creative Support & Services pages.

5. Stage 3 – Mass production in Asia (10–25 business days)

When your sample is approved and the purchase order is confirmed, the project moves into mass production. Timelines vary by structure, quantity and finishing complexity, but most export-oriented Asian factories follow a similar pattern:

- Material booking & color proofing: 2–4 business days.

- Printing & lamination: 3–7 business days.

- Special finishes: hot foil, embossing/debossing, spot UV, etc. add 2–5 days.

- Handwork & assembly: 3–10 days depending on box style and quantity.

- Insert production: EVA foam, paperboard dividers, molded pulp, etc. may run in parallel.

Typical mass production lead times at GPLPAK:

- Simple folding cartons: around 10–12 business days after sample approval.

- Corrugated mailer or shipping boxes: around 10–15 business days.

- Luxury rigid gift boxes with complex finishes: 15–25 business days.

These are realistic ranges, not guaranteed dates. For very large volume campaigns or highly specialized finishing, your account manager will provide a project-specific schedule.

6. Stage 4 – Quality control, packing & export preparation (2–5 business days)

Before your packaging leaves the factory, it must pass quality checks and be repacked into export cartons or pallets. This step often overlaps with the final days of production but still deserves its own time buffer.

What normally happens in this stage:

- In-line process checks during printing and assembly.

- Final AQL inspection (internal or 3rd-party) on finished goods.

- Counting, inner-carton packing and outer export carton packing.

- Labeling, palletization and preparation of packing lists.

- Booking containers or air freight space and arranging loading.

GPLPAK’s Factory Services and Packing procedures are designed to make sure your packaging arrives in good condition, not crushed inside the container.

7. Stage 5 – International shipping from Asia (3–40 calendar days)

Production lead time and transport lead time are two different things. Even when your packaging is finished on time, choosing the wrong logistics method can still delay your launch.

*Transit time estimates are port-to-port or hub-to-hub and exclude customs clearance and last-mile delivery. Always confirm route-specific schedules with your freight forwarder or with GPLPAK’s delivery management team.

8. How GPLPAK shortens lead time without sacrificing quality

As an Asia-based manufacturer focused on export projects, GPLPAK has built its processes around predictable timelines and proactive communication. A few concrete ways we help brands save time:

- In-house structural design and packaging consultation to avoid re-doing dielines later.

- Early material selection based on readily available, export-grade boards and specialty papers.

- Digital color proofs and controlled pre-production samples to reduce approval loops.

- Parallel production of inserts (EVA, paperboard, molded pulp) where possible.

- Standardized export packing solutions that avoid repacking at destination.

- Dedicated project managers who anticipate holidays and peak seasons in Asia.

If you are planning a seasonal campaign – such as holiday sets, limited-edition chocolate packaging or clothing boxes for retail – we recommend contacting us at least one season ahead so we can reserve production capacity.

Plan your next project with a realistic lead time

Share your product, target markets and launch dates, and our engineers will map out a customized communication → sampling → production → shipping timeline for you.

Request a tailored lead time plan↗9. Exceptional situations that can impact lead time – and how to manage them

Even with the best planning, some factors are outside the control of any single factory or brand. Understanding these risks – and building mitigation plans – is essential when sourcing packaging from Asia.

📈Trade disputes & sudden tariff changes

Trade tensions (for example, tariff changes between major economies) can cause sudden cost increases, port congestion or tighter customs checks.

- Delays in customs clearance while regulations are updated.

- Re-routing through alternative ports or shipping modes.

GPLPAK mitigation:

- Keep you informed about emerging regulatory changes affecting packaging imports.

- Help you evaluate alternative ports or Incoterms if the original route becomes too risky.

🚢Canal blockages & port congestion

Events such as canal blockages or port congestion can extend sea freight transit by weeks, even when your packaging was produced on time.

- Longer transit times on specific routes.

- Schedule changes or cancelled sailings.

GPLPAK mitigation:

- Propose split shipments: small urgent quantity by air, balance by sea.

- Work with your forwarder to explore alternative ports or rail corridors.

🚂Railway accidents & corridor disruptions

Asia–Europe rail routes are an attractive middle-option between air and sea, but they can be affected by local disruptions or geopolitical events.

- Temporary suspension of rail services on specific corridors.

- Rerouting that adds extra days to transit.

GPLPAK mitigation:

- Switch affected shipments to sea or air when rail becomes unreliable.

- Plan rail shipments primarily for replenishment, not first launches.

🛃Customs inspections & “strict checks” periods

Customs authorities periodically intensify inspections, leading to random checks or 100% inspections for certain product codes or origins.

- Delays of several days or even weeks at destination port.

- Additional storage or inspection charges.

GPLPAK mitigation & solutions:

- Split shipments and channels: send a first emergency batch by air, and the rest by sea or rail through different hubs.

- Provide full and accurate documentation (packing lists, HS codes, material declarations) to reduce inspection risk.

- Coordinate closely with your customs broker to pre-clear expected questions about materials or labeling.

🎎Major public holidays in Asia

Chinese New Year, Golden Week and other regional holidays can temporarily reduce production capacity and slow down logistics.

- Factories closing for 7–15 days or operating with limited staff.

- Port congestion before and after the holiday period.

GPLPAK mitigation:

- Share holiday calendars and recommend cut-off dates well in advance.

- Prioritize production for confirmed orders ahead of peak closure periods.

🌋Force majeure: accidents, natural disasters, lockdowns

Events like major traffic accidents, floods, earthquakes or regional lockdowns may affect either the factory itself or key logistics infrastructure.

- Temporary inability to ship from specific ports or warehouses.

- Damage to goods during transit due to unforeseen incidents.

GPLPAK mitigation & commitment:

- Work with multiple logistics providers and routes to restore flows quickly.

- For damage or loss directly linked to our production or packing errors, we will remake goods or compensate within the agreed commercial framework.

- For genuine force majeure during transport, we assist you in claim handling and, where necessary, prioritize a re-production schedule to protect your market commitments.

When risks are known (for example, ports under pressure or announced trade measures), GPLPAK recommends building additional buffer days into your project plan or splitting shipments by mode and route.

10. FAQ: lead time for custom packaging production in Asia

Q1. Can you handle rush orders?

In many cases, yes – especially when we are repeating an existing structure or artwork. Rush projects usually rely on:

- Skipping or compressing sampling (using an approved “golden sample”).

- Running production in parallel across multiple lines.

- Using air freight or courier instead of sea freight.

However, we never compromise on basic quality controls just to save time. Your GPLPAK project manager will transparently explain what is realistic.

Q2. How much faster is a repeat order compared with a first order?

Repeat orders are significantly faster because tooling, dielines and color standards already exist. For many projects, we can go directly from PO confirmation to production in a few days without new sampling, as long as there are no artwork or structure changes.

Q3. When should I start talking to an Asian packaging supplier before launch?

For seasonal launches and new product lines, we recommend starting 2–4 months ahead of your desired in-market date. This allows time for structural development, sampling, mass production and economical sea freight, plus a reasonable buffer for unexpected events.

Q4. Can GPLPAK help coordinate logistics, or do I need my own forwarder?

Both options are possible. Many clients use their own freight partners, while others prefer GPLPAK to handle door-to-port or door-to-door delivery. Our Delivery Management support ensures your packaging is packed and documented in line with your logistics plan.

Q5. What if something goes wrong with my order?

If issues are caused by our production, printing or packing, GPLPAK will either remake the affected goods or compensate according to the agreed quality and claim procedure. When delays are caused by true force majeure (such as natural disasters or transport accidents), we prioritize a re-production plan and help you work with insurers and forwarders to protect your launch as much as possible.

Still unsure about your project’s realistic lead time?

Share your box type, quantity and destination, and we will put together a clear Gantt-style timing with communication, sampling, production and shipping clearly mapped.

Get a free lead time assessment↗

Hot News

Hot News