A buyer-ready guide for car accessory brands, private labels, and distributors sourcing cylinder tissue packaging that fits cup holders, holds up in real driving conditions, and supports sustainability claims without compliance headaches.

How to choose the right paper tube structure, materials, and finishes for a cup-holder tissue cylinder—and how to prepare the compliance documents buyers often request for EU/US retail, e-commerce, and global distribution.

If you’re sourcing for an automotive accessory line, a promotional gift program, or a retail-ready SKU refresh, this post helps you create a specification that factories can quote accurately—without trial-and-error sampling.

Cylinder tissue boxes for car cup holders are compact paper tube packages designed to sit securely in standard vehicle cup holders while dispensing tissues smoothly—without collapsing, tipping, or looking “cheap” on the dashboard.

Sustainability in automotive accessories isn’t only about brand image—it’s also about retailer requirements, consumer expectations, and the growing need to substantiate environmental claims with clear material choices and documentation.

If your catalog includes multiple packaging structures, you may also want to compare tube packaging to other formats on GPLPAK: Tube Boxes • Rigid Boxes • All Products

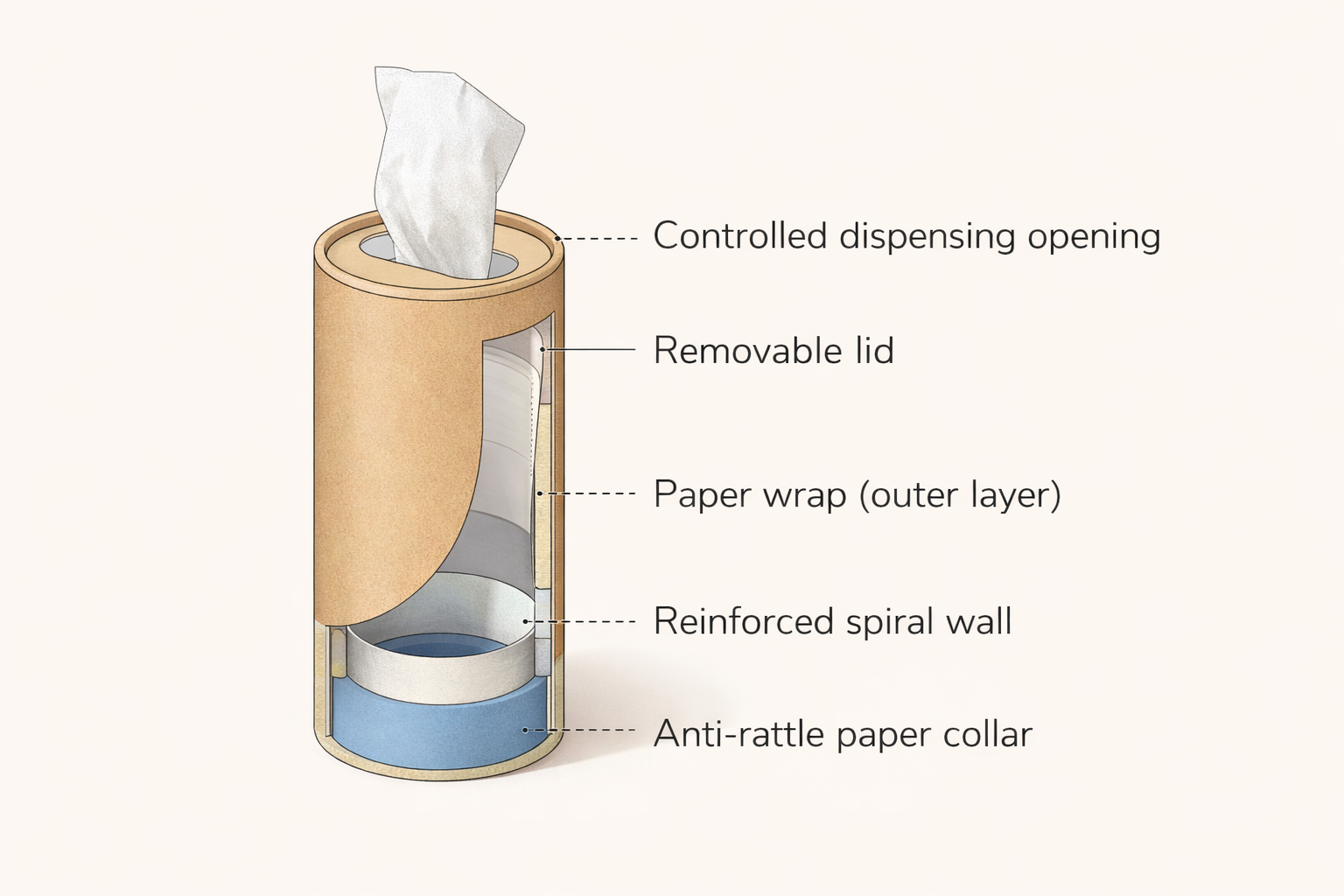

A “paper tube” sounds simple—until you quote it. For a cup-holder tissue cylinder, structure choices affect stability, cost, recyclability, and user experience.

| Option | Best for | Key trade-offs |

|---|---|---|

| Spiral-wound tube | Balanced strength + cost; most common for consumer packaging | Edge finish selection matters for premium feel |

| Convolute-wound tube | Higher strength / tighter wall tolerance where needed | Typically higher cost; not always necessary for tissues |

| Composite / reinforced designs | Hot climates, heavy handling, long supply chains | More materials = more design decisions for recyclability |

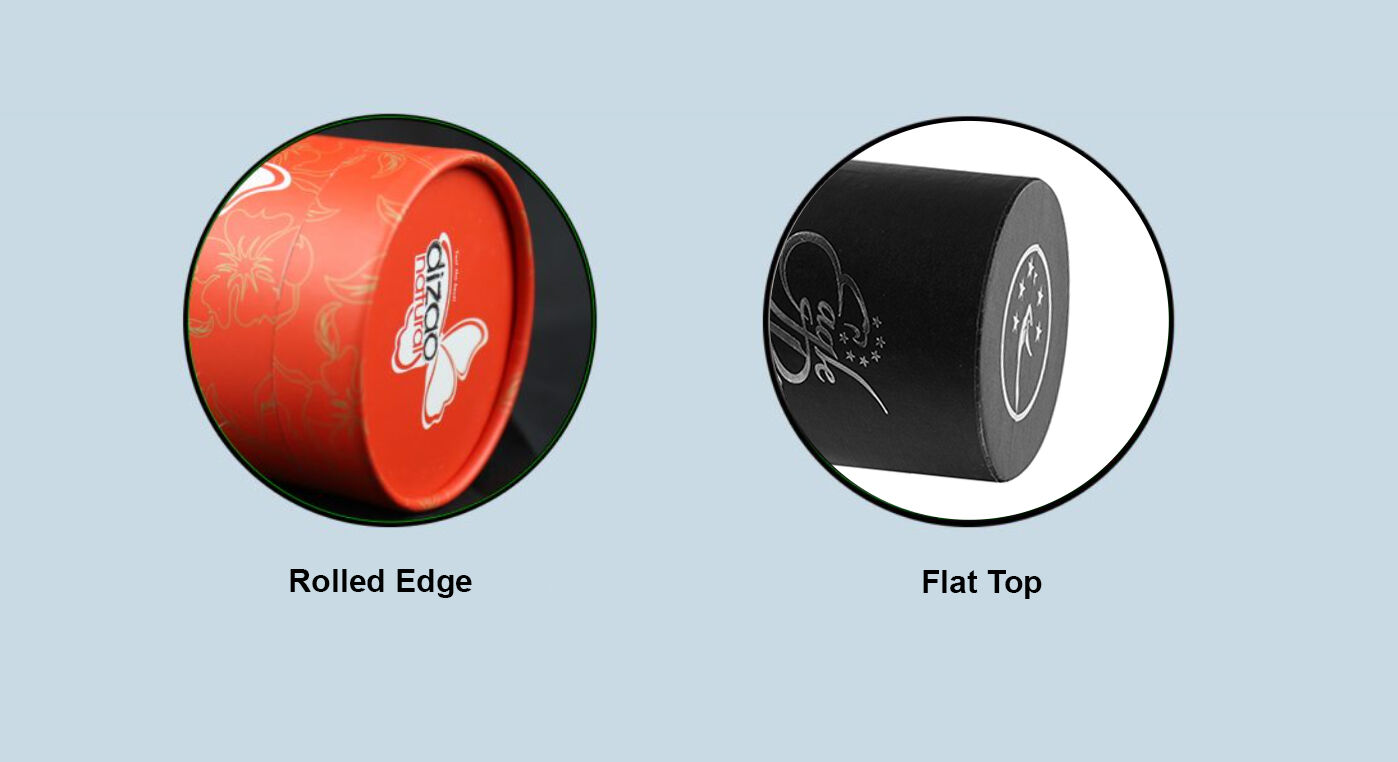

Rolled edges can improve durability and tactile quality; flat edges can look clean and minimal. Choose based on your brand positioning and target price point.

The lid can be paperboard, a hybrid cap, or a structured cover with a controlled dispensing opening—critical for “one hand use” in a vehicle.

“Eco-friendly” isn’t one material—it’s a set of decisions. The most credible approach is to choose a fiber-based structure first, then evaluate printing, coatings, and adhesives through the lens of recyclability and restricted-substance risk.

Coatings improve rub resistance and moisture tolerance—useful in cars. But heavy plastic lamination can reduce recyclability in many local systems. A more sustainability-aligned strategy is to choose lighter, more compatible protection methods where possible (and be precise about what you claim).

| Protection method | Why brands choose it | Eco/Compliance considerations |

|---|---|---|

| Water-based varnish | Basic scuff protection, cleaner feel | Typically easier for fiber-based recovery than thick films (still validate locally) |

| Soft-touch coating | Premium tactile experience | Confirm abrasion performance and restricted substance requirements for your market |

| Film lamination | Strong moisture and rub resistance | May limit recyclability; consider it only when performance truly demands it |

If you’re building an eco-ready packaging roadmap across multiple SKUs, GPLPAK’s sustainability and documentation support can be discussed here: Packaging Consultation.

Automotive accessories packaging faces “small but constant” stress: cabin heat, vibrations, friction, and occasional spills. A good paper tube design anticipates those realities.

Compliance expectations differ by market and channel, but the buyer’s goal is consistent: reduce risk. The smartest approach is to build a “ready-to-share” document set for your cylinder tissue packaging.

Buyers want packaging that supports reduction goals, uses fiber-based materials where possible, and avoids misleading claims. Clear material composition and end-of-life guidance matter.

Inks, coatings, and adhesives are the typical risk points. Buyers often request statements about restricted substances and supply chain transparency.

| Document / proof | Why it’s requested | Notes for cylinder tissue tubes |

|---|---|---|

| Material specification sheet | Confirms paper type, thickness, and structure | Include tube wall thickness, outer wrap, and lid materials |

| Certification availability statement | Supports sourcing requirements | Many buyers request certified paper availability for eco programs |

| Restricted substances / compliance statement | Reduces regulatory and retailer risk | Cover inks, coatings, adhesives, and any non-paper components |

| Packaging labeling guidance | Helps with sorting and consumer clarity | Keep claims precise; avoid broad “100% recyclable” unless proven for target markets |

| Test reports (as needed) | Validates performance | Scuff, drop, compression are common for car accessory SKUs |

At GPLPAK, we often support buyers by organizing the above into a single “quote-ready” pack—so your product team, compliance team, and procurement team can approve faster. See: Packaging Consultation.

When buyers send vague requests like “paper tube for car tissue,” quotes become inconsistent. Use the checklist below to get accurate pricing, faster sampling, and fewer revisions.

| Specification item | Recommended way to define it |

|---|---|

| Fit in cup holder | Provide the cup holder diameter range or a reference diameter (OD target + tolerance) |

| Dispensing experience | Define “one tissue at a time” requirement and whether reseal is needed |

| Eco priority | Rank priorities: recycled content, certified paper availability, low-plastic finish, etc. |

| Channel | Retail shelf, DTC, Amazon-style shipping—impacts durability and labeling needs |

Share your target size, brand artwork, and destination market. GPLPAK can recommend the right paper tube structure and finish for cup-holder performance while keeping your sustainability story clean and credible.

If you’re comparing packaging partners, this buyer-oriented guide may also help: 7 Factors to Consider When Selecting a Packaging Manufacturer.

They can—if the structure, adhesives, and outer protection are selected for the environment. For hot climates and long driving hours, prioritize a stable tube wall, a rub-resistant outer finish, and an opening design that prevents tissue bunching.

Not always. Many brands start with a water-based protective finish and optimize paper selection and surface texture. Lamination can increase resistance, but it may complicate recyclability depending on local systems—choose it only if performance requires it.

There’s no universal size because cup holders vary. The most reliable method is to define your target outer diameter range (OD) and share a reference cup holder measurement during sampling. If you sell globally, consider designing for the most common fit range.

B2B buyers typically ask for a material specification sheet, certification availability statements (for fiber sourcing programs), and restricted-substances related statements for inks/coatings/adhesives. Performance test reports may also be requested for retail or e-commerce.

Yes. GPLPAK supports custom sizing, full-color printing, and premium effects like foil stamping and embossing—often with a minimalist approach that fits Western luxury aesthetics while keeping the structure largely fiber-based.

Send your target dimensions (or cup holder fit requirements), order quantity, destination market, and artwork. You can start by viewing Tube Boxes and contacting our team via Contact Us.

If you want, we can convert your preferred tube option into a one-page spec sheet (size, materials, lid, finish, compliance pack) that you can reuse across suppliers—or send directly to GPLPAK for faster sampling.

© GPLPAK • Custom Paper Tube & Luxury Packaging Solutions

Hot News

Hot News2025-05-27

2025-09-10

2025-07-28

2025-07-30

2025-08-03

2025-08-06