The packaging industry has witnessed a remarkable transformation in recent years, with the traditional paper box evolving from a simple container into a sophisticated marketing tool and environmental solution. Modern businesses across various sectors are recognizing that packaging extends far beyond mere protection, serving as a critical touchpoint for brand communication and consumer engagement. As sustainability concerns continue to shape consumer preferences, the paper box has emerged as a frontrunner in eco-friendly packaging solutions, offering versatility, customization options, and environmental benefits that align with contemporary market demands.

Environmental Impact and Sustainability Benefits

Carbon Footprint Reduction Through Paper Box Solutions

The shift toward sustainable packaging has positioned the paper box as a leading alternative to plastic and other non-biodegradable materials. Manufacturing processes for paper-based packaging typically generate significantly lower carbon emissions compared to plastic production, making each paper box a more environmentally responsible choice. The renewable nature of paper materials, primarily sourced from managed forests, ensures that packaging solutions can be produced without depleting finite resources. Companies implementing paper box packaging strategies often report measurable reductions in their overall environmental footprint, contributing to corporate sustainability goals and meeting increasingly stringent environmental regulations.

Advanced recycling technologies have further enhanced the environmental credentials of paper box packaging, with modern recycling facilities achieving recovery rates exceeding 80% for properly designed paper containers. The circular economy model becomes particularly effective when businesses adopt paper box solutions that incorporate recycled content while maintaining structural integrity and visual appeal. This approach not only reduces waste streams but also creates economic incentives for continued investment in sustainable packaging infrastructure.

Biodegradability and Waste Management Advantages

Unlike synthetic packaging materials that can persist in landfills for decades, a properly designed paper box typically decomposes within months under appropriate conditions. This rapid biodegradation process significantly reduces long-term waste accumulation and minimizes environmental impact on ecosystems. The composting potential of paper box materials provides additional end-of-life options, allowing organic waste facilities to process packaging materials alongside other biodegradable waste streams.

Municipal waste management systems benefit considerably from increased adoption of paper box packaging, as these materials integrate seamlessly with existing recycling infrastructure. The sorting and processing of paper-based packaging requires less specialized equipment compared to complex plastic recycling operations, resulting in more efficient waste management processes and reduced operational costs for municipalities. Consumer education initiatives around proper disposal methods for paper box packaging have shown remarkable success rates, with participation in recycling programs increasing substantially when clear guidelines are provided.

Design Innovation and Customization Capabilities

Advanced Printing and Finishing Technologies

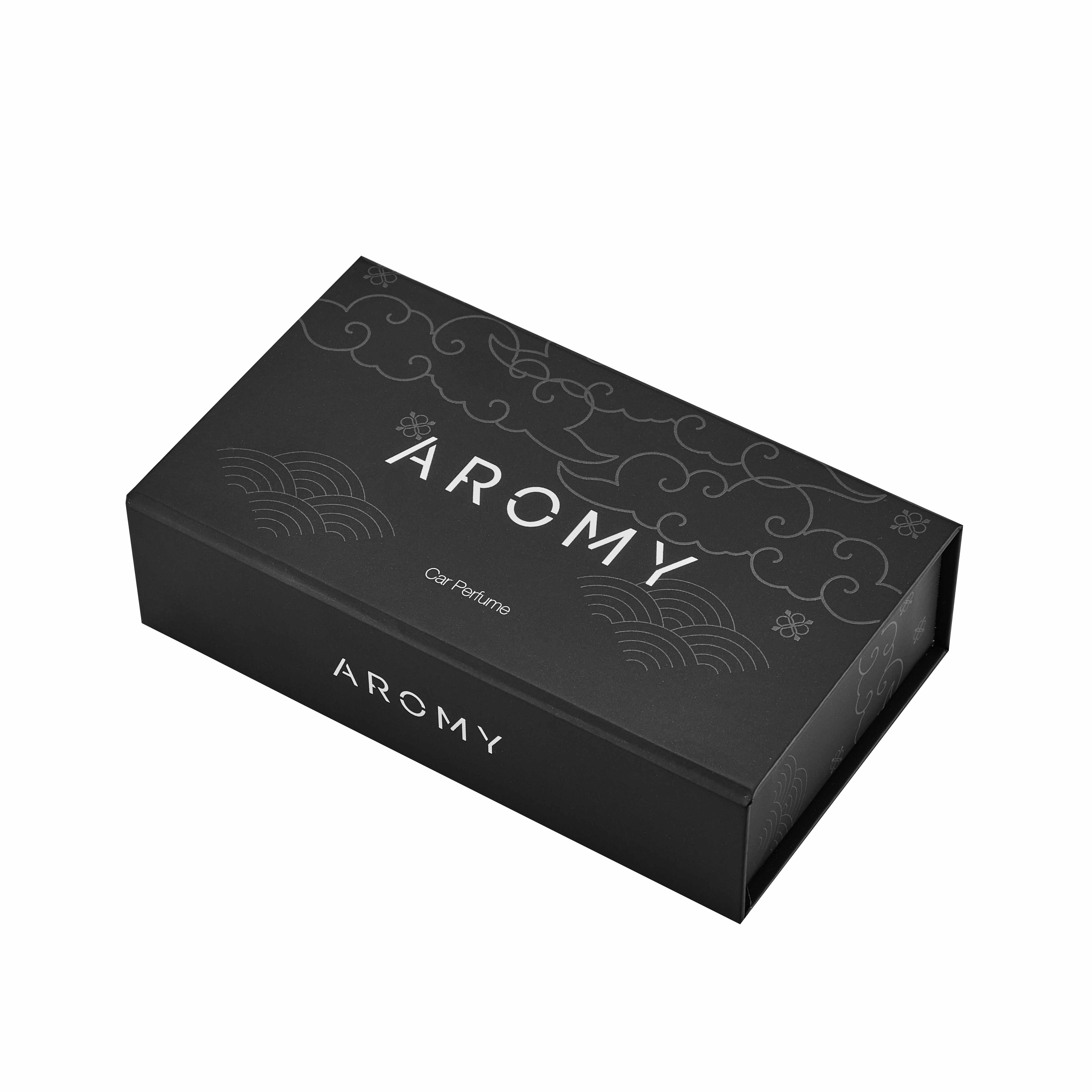

Contemporary paper box manufacturing leverages cutting-edge printing technologies that deliver exceptional visual quality and brand differentiation opportunities. Digital printing capabilities enable cost-effective short-run productions, allowing businesses to create customized packaging solutions without the traditional overhead costs associated with large minimum orders. High-resolution printing techniques can reproduce intricate designs, photographic images, and complex color gradients on paper box surfaces, creating packaging that rivals traditional retail display methods in visual impact.

Specialized finishing options such as embossing, debossing, foil stamping, and spot UV coating provide tactile and visual enhancement opportunities that transform a standard paper box into a premium packaging experience. These finishing techniques can highlight brand elements, create textural interest, and communicate quality positioning without relying solely on expensive materials. The combination of advanced printing and finishing technologies enables brands to achieve sophisticated packaging aesthetics while maintaining the environmental benefits associated with paper-based solutions.

Structural Engineering and Functional Design

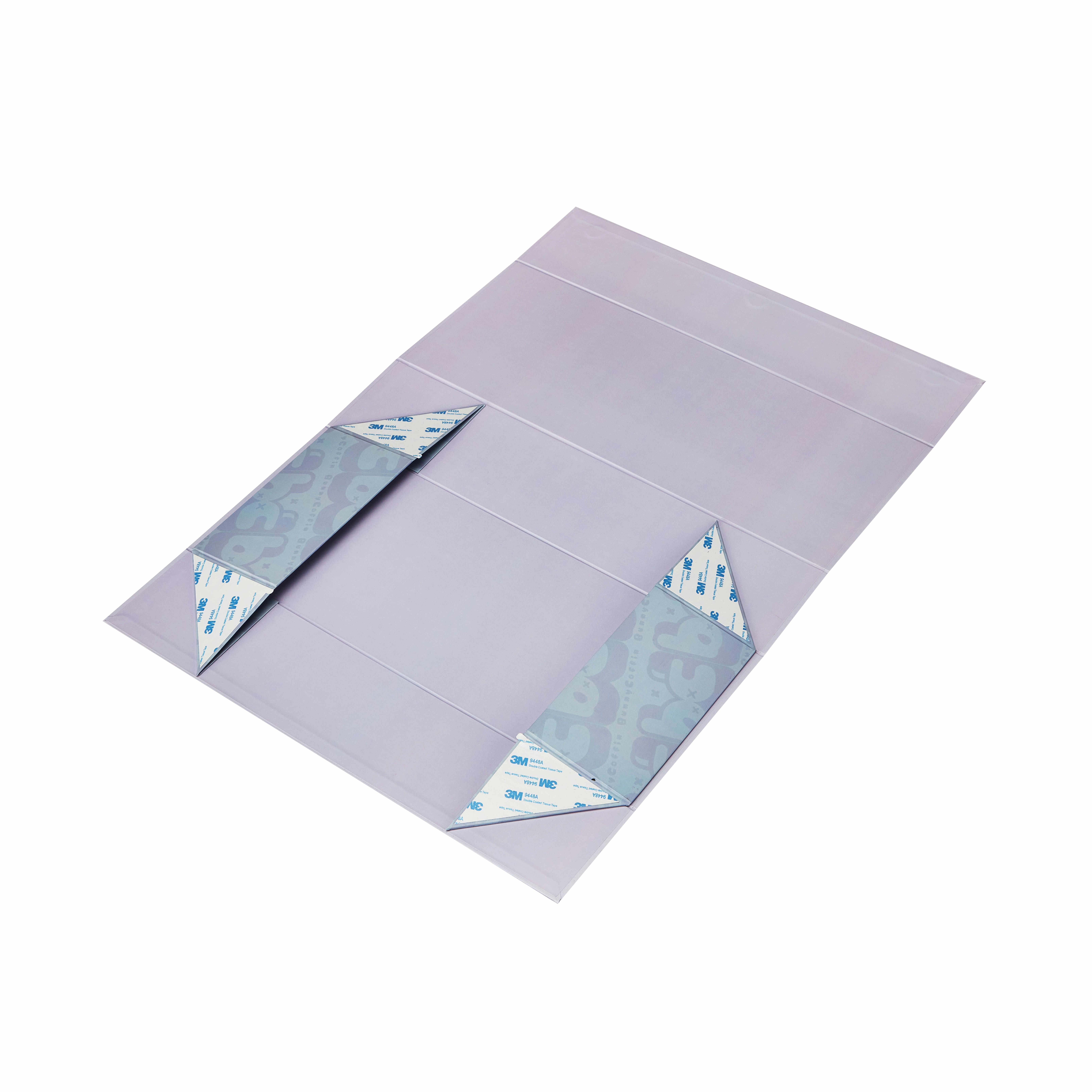

Modern paper box design incorporates sophisticated structural engineering principles that maximize protection while minimizing material usage. Advanced die-cutting technologies enable the creation of complex folding patterns and interlocking mechanisms that provide superior strength and durability compared to traditional box designs. These engineering innovations allow a single paper box to perform multiple functions, such as display presentation, shipping protection, and storage organization, reducing the need for additional packaging components.

Customization capabilities extend beyond visual elements to include functional modifications such as window panels, carrying handles, compartmentalization, and specialized closures. Each paper box can be engineered to accommodate specific product dimensions, weight requirements, and handling considerations, ensuring optimal protection while maintaining cost efficiency. The modular nature of paper box construction allows for easy assembly, reducing labor costs and storage requirements for businesses implementing these packaging solutions.

Market Applications and Industry Adoption

E-commerce and Shipping Solutions

The explosive growth of e-commerce has created unprecedented demand for reliable, cost-effective packaging solutions, positioning the paper box as an ideal solution for online retail operations. Shipping requirements for e-commerce demand packaging that can withstand automated sorting systems, extended transit times, and varying environmental conditions while maintaining product integrity. Paper box designs specifically engineered for e-commerce applications incorporate reinforcement structures, moisture resistance treatments, and standardized dimensions that optimize shipping efficiency and reduce transportation costs.

Subscription box services have particularly embraced innovative paper box designs that enhance the unboxing experience and reinforce brand identity. These applications demonstrate how a well-designed paper box can serve as a marketing vehicle that extends brand engagement beyond the initial purchase transaction. The ability to print variable data on paper box surfaces enables personalization opportunities that create emotional connections with consumers, driving customer loyalty and repeat purchases in competitive e-commerce markets.

Retail Display and Point-of-Sale Applications

Retail environments increasingly rely on paper box packaging that serves dual purposes as product protection and promotional display material. Counter displays, shelf-ready packaging, and promotional boxes constructed from paper materials provide cost-effective merchandising solutions that can be quickly deployed and easily updated for seasonal campaigns or product launches. The lightweight nature of paper box construction reduces shipping costs for retail display materials while maintaining sufficient durability for extended store use.

Point-of-sale applications benefit from the printability and customization options available with paper box solutions, enabling retailers to create cohesive brand experiences that integrate packaging with broader marketing campaigns. The ability to produce small quantities of specialized paper box designs supports limited-time promotions, regional marketing initiatives, and product testing scenarios without significant inventory investment or waste generation.

Manufacturing Processes and Quality Control

Production Efficiency and Scalability

Modern paper box manufacturing processes have achieved remarkable efficiency improvements through automation and process optimization, enabling cost-effective production across various volume requirements. High-speed converting equipment can produce thousands of paper box blanks per hour while maintaining precise dimensional tolerances and consistent quality standards. These manufacturing capabilities support both large-scale production runs and smaller customized orders, providing flexibility for businesses with varying packaging needs.

Quality control systems integrated into paper box production lines employ advanced inspection technologies that monitor dimensional accuracy, printing registration, and structural integrity throughout the manufacturing process. Automated reject systems ensure that only paper box products meeting specified criteria reach final packaging and shipping stages, minimizing quality-related issues and customer complaints. Statistical process control methodologies enable continuous improvement initiatives that enhance efficiency while reducing waste in paper box manufacturing operations.

Material Selection and Performance Optimization

The selection of appropriate paper grades and weights plays a crucial role in optimizing paper box performance for specific applications. Different paper types offer varying characteristics in terms of strength, printability, barrier properties, and cost considerations, requiring careful evaluation to match material properties with intended use requirements. Corrugated paper box constructions provide enhanced strength and cushioning properties for shipping applications, while solid bleached sulfate grades offer superior printing surfaces for high-end retail packaging.

Performance testing protocols ensure that each paper box design meets or exceeds industry standards for compression strength, edge crush resistance, and burst strength. These testing procedures validate packaging performance under simulated shipping and handling conditions, providing confidence that products will arrive at their destination in optimal condition. Advanced testing methodologies can predict paper box performance under various environmental conditions, enabling optimization of material specifications and structural designs for specific geographic markets or seasonal requirements.

Cost-Effectiveness and Economic Benefits

Total Cost of Ownership Analysis

While initial material costs for paper box packaging may vary compared to alternative packaging solutions, comprehensive total cost of ownership analysis often reveals significant economic advantages. Reduced shipping weights associated with paper box packaging translate directly to lower transportation costs, particularly for businesses with high-volume shipping operations. The ease of flat storage for unassembled paper box blanks minimizes warehouse space requirements and inventory carrying costs compared to pre-formed rigid packaging alternatives.

Labor efficiency improvements result from the straightforward assembly processes associated with most paper box designs, reducing packaging time and associated labor costs. Automated packaging equipment designed for paper box applications typically requires lower capital investment and maintenance costs compared to machinery designed for alternative packaging materials. These operational efficiencies compound over time, creating substantial cost savings that enhance overall profitability for businesses implementing paper box packaging solutions.

Supply Chain Optimization Benefits

The widespread availability of paper box manufacturing capabilities reduces supply chain complexity and minimizes sourcing risks for businesses requiring packaging solutions. Regional production facilities can often fulfill paper box requirements with shorter lead times and reduced transportation costs compared to specialized packaging materials that may require global sourcing. This geographic distribution of manufacturing capabilities provides supply chain resilience and flexibility for businesses operating in multiple markets.

Standardization opportunities within paper box designs enable economies of scale that reduce per-unit costs while maintaining customization options for brand differentiation. Modular design approaches allow businesses to leverage common paper box components across multiple product lines, simplifying inventory management and reducing complexity in procurement processes. These standardization benefits extend to printing and finishing operations, where common processes can be applied across various paper box applications to optimize production efficiency and cost management.

Future Trends and Innovation Opportunities

Smart Packaging Integration

Emerging technologies are creating new opportunities for integrating smart features into traditional paper box designs, enabling enhanced functionality without compromising sustainability benefits. Near-field communication tags, QR codes, and printed electronics can be seamlessly incorporated into paper box surfaces, providing interactive capabilities that enhance consumer engagement and enable supply chain tracking. These smart packaging features transform a simple paper box into an information platform that can deliver product authentication, usage instructions, and promotional content directly to consumers.

Temperature-sensitive inks and moisture indicators printed directly on paper box surfaces provide real-time monitoring capabilities for sensitive products during storage and transportation. These innovations enable proactive quality management and reduce product losses due to environmental exposure, creating additional value beyond traditional packaging functions. The integration of smart features into paper box designs represents a convergence of sustainability and technology that addresses contemporary market demands for both environmental responsibility and enhanced functionality.

Advanced Materials and Barrier Technologies

Research and development initiatives are expanding the application possibilities for paper box packaging through advanced barrier coatings and material treatments. Water-based barrier coatings provide moisture and grease resistance while maintaining recyclability and compostability characteristics that align with sustainability objectives. These technological advances enable paper box applications in market segments previously dominated by plastic packaging, such as food service and pharmaceutical applications.

Nanotechnology applications in paper box manufacturing are creating opportunities for enhanced performance characteristics without significant material additions. Nano-coatings can provide antimicrobial properties, improved barrier performance, and enhanced strength characteristics while maintaining the fundamental biodegradability of paper-based packaging. These advanced materials represent the future evolution of paper box technology, expanding application possibilities while preserving environmental benefits that drive market adoption.

FAQ

What makes paper box packaging more environmentally friendly than plastic alternatives

Paper box packaging offers superior environmental benefits due to its renewable raw materials, biodegradable properties, and established recycling infrastructure. Unlike plastic packaging that can persist in the environment for decades, paper box materials decompose naturally within months under appropriate conditions. The manufacturing process for paper box packaging typically generates lower carbon emissions compared to plastic production, and the materials can be sourced from sustainably managed forests that sequester carbon during growth cycles.

How do modern printing technologies enhance paper box customization options

Advanced digital printing technologies enable high-quality, cost-effective customization for paper box packaging across various production volumes. These printing capabilities support complex designs, photographic reproduction, and variable data printing that allows for personalization and targeted marketing applications. Specialized finishing techniques such as embossing, foil stamping, and spot coatings can be applied to create premium paper box packaging that enhances brand perception and consumer engagement while maintaining environmental benefits.

What structural engineering considerations are important for paper box design

Effective paper box design requires careful consideration of load-bearing requirements, stacking strength, and compression resistance to ensure adequate product protection during shipping and handling. Structural elements such as corner reinforcements, bottom lock designs, and sidewall configurations must be optimized for specific applications while minimizing material usage. Advanced die-cutting technologies enable complex folding patterns and interlocking mechanisms that provide superior strength without requiring additional materials or adhesives.

How do paper box solutions compare in cost-effectiveness to alternative packaging materials

Total cost analysis for paper box packaging must consider initial material costs, shipping weight reductions, storage efficiency, and end-of-life disposal costs to provide accurate comparisons with alternative packaging materials. While material costs may vary, paper box packaging often provides overall cost advantages through reduced shipping expenses due to lighter weight, simplified assembly processes that reduce labor costs, and compatibility with existing recycling infrastructure that minimizes waste disposal fees. Long-term cost benefits become particularly significant for businesses with high-volume packaging requirements.

Table of Contents

- Environmental Impact and Sustainability Benefits

- Design Innovation and Customization Capabilities

- Market Applications and Industry Adoption

- Manufacturing Processes and Quality Control

- Cost-Effectiveness and Economic Benefits

- Future Trends and Innovation Opportunities

-

FAQ

- What makes paper box packaging more environmentally friendly than plastic alternatives

- How do modern printing technologies enhance paper box customization options

- What structural engineering considerations are important for paper box design

- How do paper box solutions compare in cost-effectiveness to alternative packaging materials