For modern brands, packaging is not just a box—it is a promise of quality, a marketing surface, and often the first physical touchpoint with your customer. Choosing the wrong supplier can lead to delays, colour inconsistencies, damaged goods, and frustrated buyers. This guide walks you through a practical, step-by-step process to find reliable packaging partners, with insights from GPLPAK, a China-based custom packaging manufacturer with 15+ years of export experience.

1. Why Your Packaging Supplier Matters More Than Ever

Customers today judge your brand long before they see or use the product. Unboxing videos, social media photos, and retail displays all amplify one thing: the quality of your packaging. A reliable packaging supplier determines whether your launch arrives on time, whether your colours match your brand guidelines, and whether your products survive shipping without damage.

For brands in wine & beverages, cosmetics, fragrance, jewellery, chocolate and gifting, packaging is part of the value proposition. A trustworthy supplier must therefore deliver:

- Consistent quality across multiple production runs

- On-time delivery for seasonal and promotion-driven launches

- Scalable capacity as your order volume grows

- Technical support on structure, materials and protective inserts

- Alignment with your sustainability and brand positioning

Expert insight from GPLPAK: As a direct manufacturer with more than 15 years of experience in handmade rigid boxes and

custom paper packaging, GPLPAK sees the best outcomes when brands treat their supplier as a long-term partner rather than a one-off vendor.

2. Step 1 — Define Your Brand and Packaging Requirements

Before you start contacting suppliers, you need a clear internal brief. Strong brands know exactly what they are buying, which makes evaluating suppliers much easier.

2.1 Clarify your product and application

Start by mapping how the packaging will be used:

- Product category: wine/spirits, perfume, cosmetics, jewellery, apparel, chocolate, gift sets, etc.

- Channel: e-commerce shipping, retail display, subscription boxes, PR/influencer kits, duty-free, etc.

- Protection needs: fragile glass bottles, heavy jars, delicate accessories, temperature-sensitive items.

2.2 Define your preferred structures and formats

Different products and channels call for different structures. A reliable supplier should offer and understand a wide range of box types such as:

- Rigid setup boxes and magnetic boxes for premium cosmetics, wine and fragrance

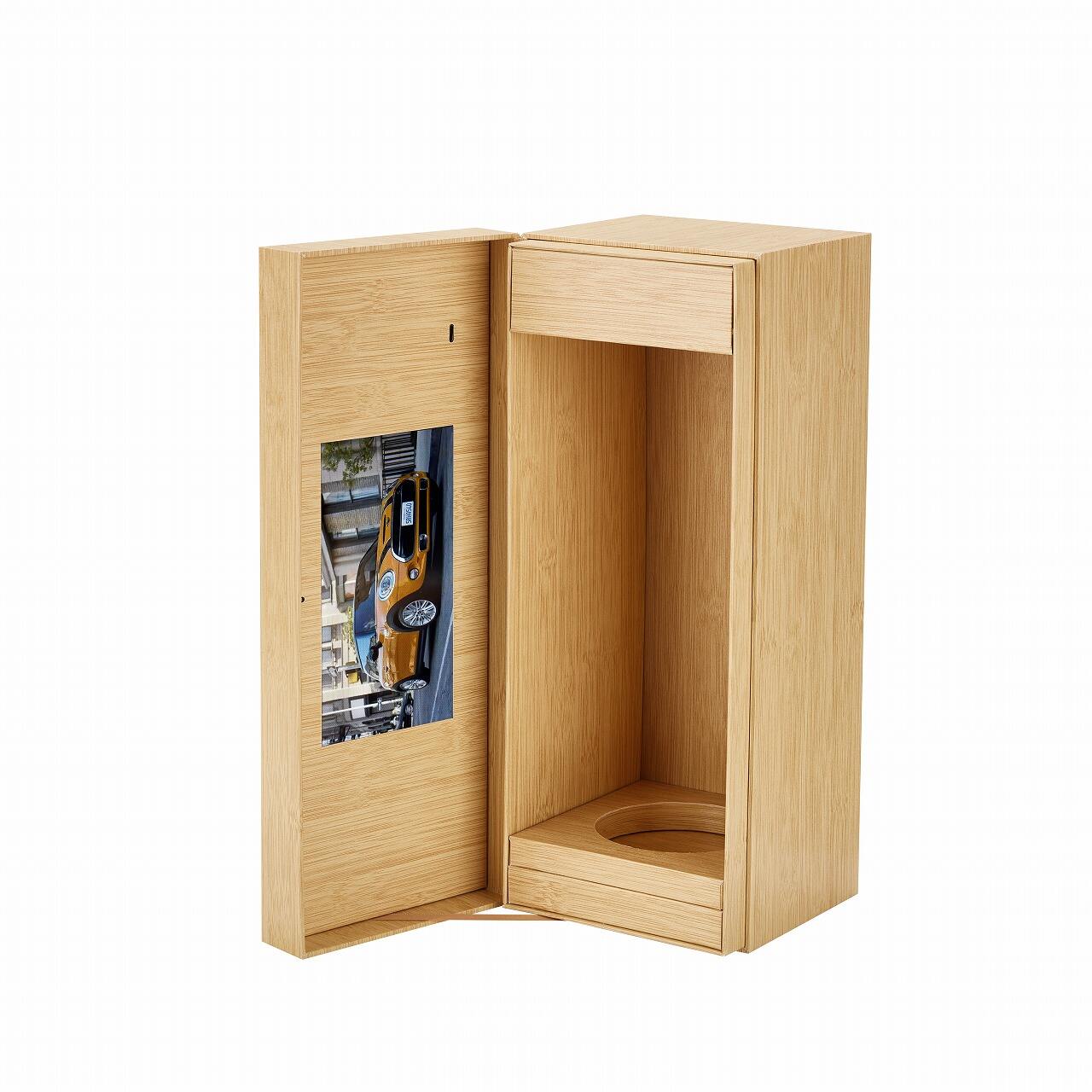

- Drawer boxes, book-shape boxes and suitcase-style boxes for storytelling and gifting

- Corrugated mailer boxes and shipping boxes for D2C and e-commerce

- Flat-fold rigid boxes and folding cartons when you need to save warehouse space

To see examples of these structures in real projects, you can review the Rigid Boxes collection on GPLPAK and the Corrugated Boxes category.

2.3 Lock in branding, printing and sustainability requirements

To compare suppliers accurately, decide on:

- Brand colours (Pantone/CMYK), logo placement and foil or embossing preferences

- Surface finishes (matte/gloss lamination, soft-touch, spot UV, metallic foil, textured paper)

- Eco requirements: FSC-certified board, recyclable or biodegradable inserts, soy-based inks etc.

3. Step 2 — Where to Search for Reliable Suppliers

3.1 Online research and digital due diligence

Most sourcing journeys start online. Search for terms like “custom packaging box manufacturer” combined with your product category or region. Look for suppliers whose websites clearly show:

- Product categories by structure and application (rigid, corrugated, drawer, tube, etc.)

- Industries served and typical use cases

- Certifications (FSC, ISO, BSCI, RoHS) and export experience

- Case studies, blogs and technical articles that demonstrate expertise

GPLPAK, for example, maintains a structured Blog section covering topics such as cost breakdowns for rigid boxes, aligner packaging, and reviews of handmade packaging manufacturers — all useful indicators that the team deeply understands packaging engineering, export logistics and brand requirements.

3.2 Offline channels: trade shows and referrals

Online research gives you a shortlist, but many brands confirm their choices through offline validation:

- International and regional packaging trade shows

- Specialised exhibitions for wine, cosmetics, fragrances and luxury gifting

- Referrals from other brand owners, agencies or fulfilment partners

At shows, inspect physical samples, check finishing quality, and ask about production lead times, MOQ and export references. A serious manufacturer will be open about processes, equipment and factory audits.

4. Step 3 — How to Evaluate Supplier Reliability

A. Technical capability

4.1 Technical capability & product range

A reliable supplier should be able to show a deep portfolio, not just a few generic models. Review whether they can handle:

- Complex structures: magnetic book boxes, story-shaped boxes, collapsible rigid boxes, triangular or pyramid boxes, etc. :contentReference

- Precision inserts: EVA, foam, cardboard or molded pulp trays tailored to your exact product dimensions

- High-end finishing: multi-colour offset printing, foil stamping, emboss/deboss, soft-touch lamination

On the GPLPAK website, individual product pages such as collapsible rigid boxes and book-style rigid boxes demonstrate the ability to turn complex concepts into manufacturable designs for luxury industries.

B. Quality & compliance

4.2 Quality processes, certifications & compliance

Strong packaging suppliers integrate quality into every step of production. Look for:

- Certifications such as FSC, ISO and BSCI that signal responsible sourcing and audited processes

- Clear QC procedures: incoming material checks, colour proofing, in-line inspections, final sampling

- Performance testing: compression, edge crush, and transit simulations for shipping boxes where relevant

GPLPAK highlights its certifications and testing mindset on multiple product pages, giving buyers confidence that materials and finishes will perform as promised, especially for fragile premium goods.

C. Sustainability

4.3 Sustainability and material choices

Brands increasingly demand packaging that balances luxury with responsibility. A reliable supplier should:

- Offer FSC-certified paper and boards as standard where possible

- Provide eco-friendly options such as soy-based inks, recyclable or biodegradable inserts and reduced-plastic constructions

- Quantify benefits, such as reduced carbon footprint from collapsible rigid boxes and optimised shipping volumes

On GPLPAK’s collapsible rigid box pages, the company shows clear data on how flat-packed designs cut storage and shipping impact — a sign that the team understands environmental as well as financial ROI for clients.

D. Service

4.4 Communication, project management & service

Packaging projects rarely go 100% according to plan. Reliable suppliers distinguish themselves through:

- Responsive communication during sampling, production and shipping

- Professional advice on design-for-manufacturing and cost optimisation

- Post-shipment support if there are quality or logistics issues

GPLPAK’s site emphasises creative support (packaging consultation, product development, design validation) and factory services (development sampling, manufacturing), which are all crucial for brand owners who need guidance from idea to finished box.

5. Step 4 — Pricing, MOQs and Total Cost of Ownership

Comparing quotes can be confusing if you only look at the unit price. Reliable suppliers will help you understand the full picture: materials, labour, finishing, sampling, freight and potential savings from smarter structures.

5.1 Understand the cost drivers

For rigid paper boxes, major cost drivers include board thickness, special papers, finishing techniques and hand assembly. GPLPAK’s article “How Much Does a Custom Rigid Paper Box Cost?” breaks down these factors in detail, explaining why premium rigid boxes typically cost more than standard folding cartons.

- Greyboard thickness (commonly 2–3 mm for luxury rigid boxes)

- Wrap materials (specialty papers, fabrics, metallic or textured stocks)

- Finishing (foil, emboss/deboss, UV, soft-touch, special die-cuts)

- Insert design and materials

- Assembly complexity and manual labour

5.2 Talk about MOQ and scaling

Minimum order quantities (MOQs) vary by structure and finishing. A reliable supplier will explain how MOQs affect cost per unit and suggest ways to scale smartly — for example, by standardising inserts or using collapsible designs to lower shipping and storage expenses.

When requesting quotations from GPLPAK or any other factory, provide detailed specs and volumes for at least three scenarios (e.g., 1,000 / 3,000 / 5,000 units). This reveals how price changes with quantity and helps you plan future growth.

6. Step 5 — Samples, Prototypes and Pilot Orders

No serious brand should skip sampling. The sample phase is where you verify colour, structure, insert fit and overall feel before committing to a bulk order.

6.1 Types of samples

A reliable supplier will usually offer several sample formats:

- White mock-up samples to validate size, structure and insert fit

- Digital print samples for quick visual checks on smaller runs

- Offset ink samples to approve final colours and paper choices prior to mass production

GPLPAK clearly states that samples can be provided before bulk orders, which is critical for risk reduction on new launches or seasonal campaigns.

7. Common Red Flags When Choosing Packaging Suppliers

As you shortlist candidates, watch out for warning signs that a vendor may not be reliable:

- Unclear ownership of the factory or lack of factory profile information

- No mention of certifications, QC, or materials testing anywhere on the site

- Inconsistent product photos or obvious stock images unrelated to packaging

- Reluctance to provide samples, or no structured sampling process

- Unrealistically low pricing with vague answers about materials and finishing

- Slow or incomplete responses to technical questions

By contrast, GPLPAK publishes a transparent cost explanation and maintains detailed category pages for structures, applications, industries and services — all markers of an established manufacturer rather than a short-term trading intermediary.

8. Why Global Brands Work with GPLPAK

A case example of what to look for in a reliable packaging supplier.

GPLPAK is a China-based factory focused on custom luxury paper packaging, including rigid boxes, collapsible boxes, corrugated shipping boxes and story-shaped boxes for wine & beverages, cosmetics, perfume, jewellery, chocolate and gifts.

-

Proven handmade box expertise: Over 15 years of rigid and handmade packaging experience for export markets.

-

Certified and audited: FSC, ISO, BSCI and RoHS certifications that support compliance for global brands.

-

End-to-end support: Packaging consultation, structural design, development sampling and mass manufacturing handled under one roof.

-

Eco-forward options: FSC-certified materials, eco-friendly inks and collapsible structures that reduce shipping and storage impact.

-

Industry-focused solutions: Dedicated packaging for cosmetics, wine & spirits, fragrance, jewellery, apparel, chocolate and more.

Brands evaluating suppliers can use GPLPAK as a benchmark: Does the vendor clearly explain its capabilities and show real product cases? Does it provide educational content, like the strategic review of custom packaging manufacturers or the guide to top handmade box makers ? If yes, they are more likely to be serious long-term partners.

9. Practical Checklist & Next Steps

To summarise, here is a quick checklist you can use when sourcing packaging suppliers for your branded products:

- Define your product, channel, protection needs and sustainability goals

- Select preferred structures and finishes that fit your brand

- Shortlist suppliers with clear product categories, certifications and export experience

- Evaluate technical capability, quality processes, sustainability and communication

- Request detailed quotations with at least three volume tiers

- Approve structural and printed samples before mass production

- Start with a pilot order, then scale once quality and service are validated

Discuss Your Next Packaging Project with GPLPAK

If you are looking for a reliable packaging supplier for your branded products, GPLPAK can support you from concept to finished box. Explore our core categories and then send us your brief for a tailored quotation.

You can also browse our Blog for more guides on rigid box costs, collapsible designs and industry-specific packaging tips.

Hot News

Hot News