produttore di scatole rigide

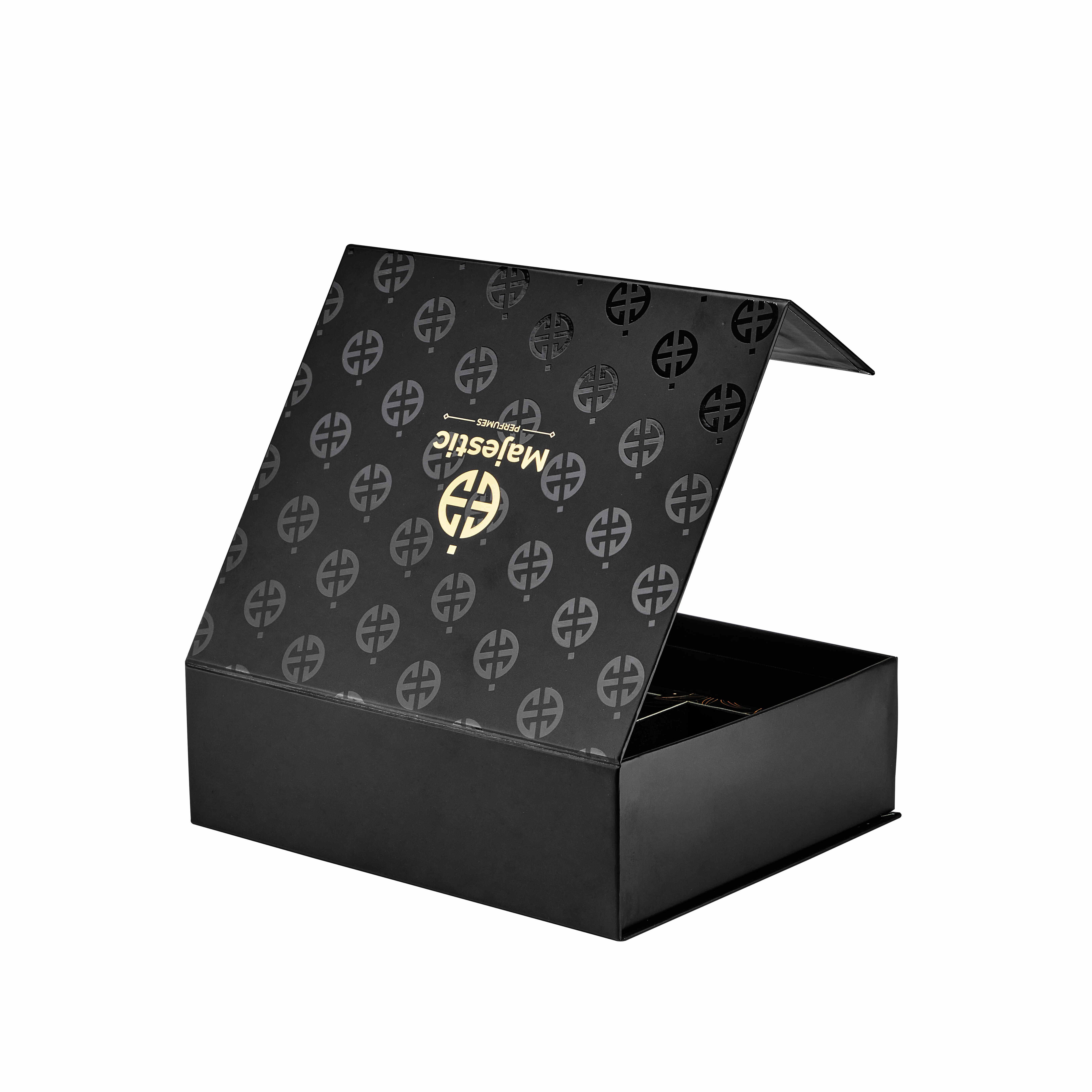

Un produttore di scatole rigide rappresenta un'installazione specializzata dedicata alla produzione di soluzioni di imballaggio di alta qualità e duratura utilizzando tecniche di produzione avanzate e materiali premium. Questi produttori impiegano attrezzature all'avanguardia e ingegneria di precisione per creare scatole progettate su misura che offrono una protezione e una presentazione superiori per vari prodotti. Il processo di produzione prevede molteplici fasi, dalla selezione dei materiali e dal taglio all'assemblaggio e al finitura, tutte eseguite con attenzione meticolosa ai dettagli. I moderni produttori di scatole rigide utilizzano sistemi automatizzati per garantire una qualità costante della produzione, incorporando funzionalità come la tecnologia di progettazione assistita da computer (CAD) per misurazioni e modelli di taglio precisi. Queste strutture sono dotate di macchine specializzate per il taglio a stampo, attrezzature per la laminatura e sistemi di controllo qualità per assicurarsi che ogni scatola rispetti le specifiche esatte. La capacità di produzione si estende a vari stili di scatole, inclusi i box telescopici, le scatole a cassetta, le scatole a libro e le scatole a collo-spalla, soddisfacendo esigenze diverse da parte di settori come il retail di lusso fino all'imballaggio elettronico. Il processo di produzione enfatizza la sostenibilità, con molti produttori che implementano pratiche eco-friendly e utilizzano materiali riciclabili mantenendo integrità strutturale e attrattiva estetica.