1) What Is Sushi Push Pop Up Tube Packaging?

Sushi push pop up tube packaging is a cylindrical container built around a simple but powerful mechanism: a movable base pushes the roll upward through the top opening. The result is a “hands cleaner” eating flow, less mess during transit, and a more engaging product reveal—especially valuable for premium rolls and modern takeaway brands.

Typical structure (buyer-friendly breakdown)

- Outer tube: Provides rigidity, stack strength, and a 360° branding canvas.

- Push-up base: Slides smoothly to elevate the roll without crushing toppings.

- Top lid: Keeps the product secure for delivery, chilling, and retail display.

Why it’s different from a traditional sushi box

- Protection: Cylinders resist squeezing better than flat cartons in delivery bags.

- Presentation: The “push reveal” looks premium and encourages social sharing.

- Portability: Designed for on-the-go consumption with minimal setup.

2) Core Use Cases for Restaurants & Sushi Brands

For B2B buyers, the smartest packaging choices are the ones that make the operation smoother while strengthening the brand. Below are the most common use cases we see from restaurant groups, premium sushi studios, and retail-focused operators.

Use Case A: Grab-and-go takeaway (commuter-friendly)

Push pop tubes are naturally designed for mobility. A secure lid, stable tube wall, and easy push-up action support “eat anywhere” moments.

Use Case B: Delivery protection for premium rolls

The tube format protects roll shape and topping integrity, reducing remakes and preserving the “as-prepared” look.

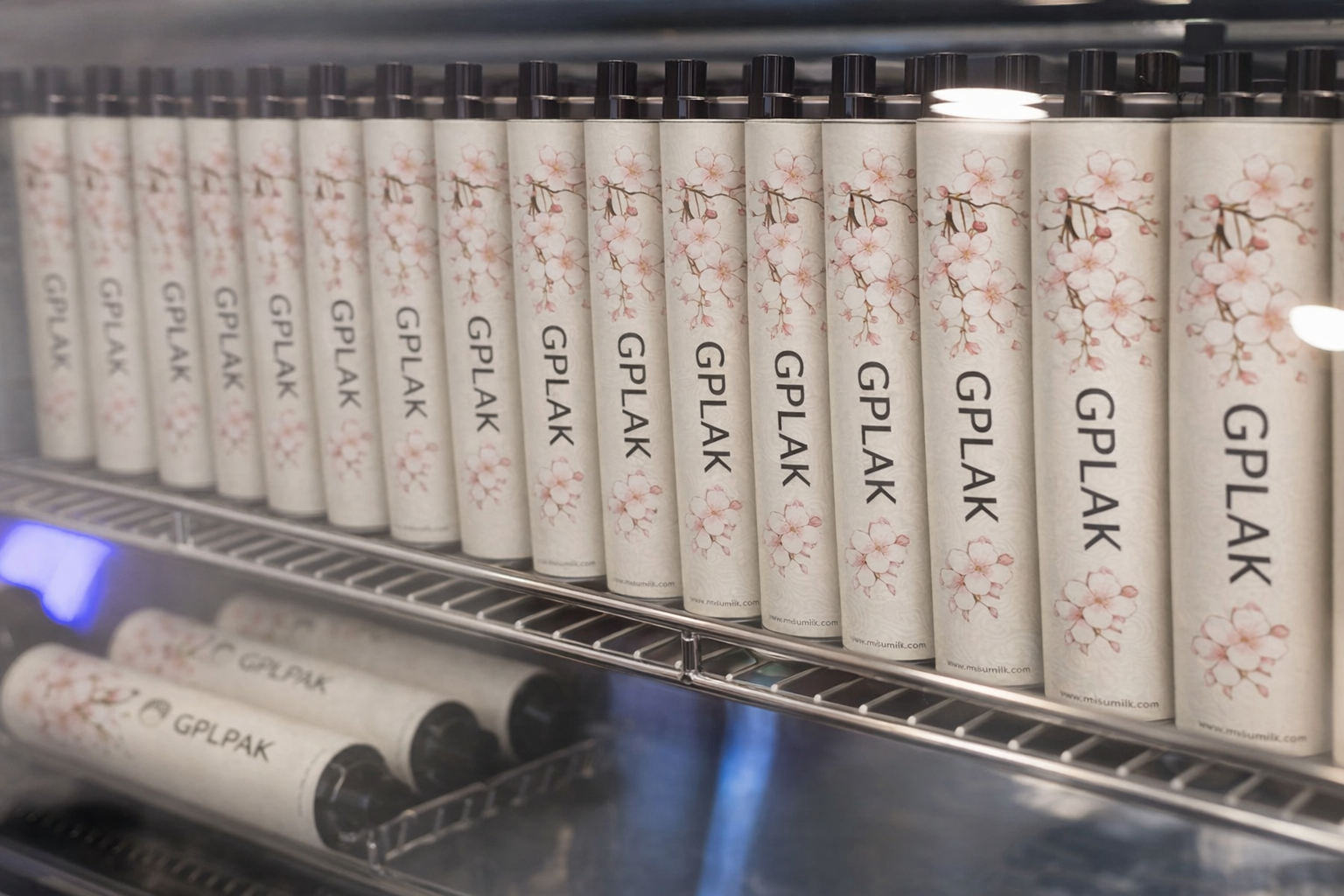

Use Case C: Retail-ready sushi in refrigerated display

Cylindrical packaging creates strong shelf presence and helps brands stand out in convenience stores and premium retail counters.

Use Case D: Pop-ups, events, and brand activations

Push pop tubes photograph well, feel modern, and can be finished with premium textures to support limited drops and collabs.

Use Case E: Menu innovation (sauce/condiment integration)

If your concept includes sauces, specify containment and sealing requirements early in the RFQ to avoid rework later.

Planning a pilot launch?

Start with a validated tube size, then upgrade to fully custom graphics and barrier options. GPLPAK supports both pilot programs and long-term procurement.

3) Key Benefits: Performance + Brand Outcomes

The strongest adoption happens when a packaging upgrade drives both operational wins and brand wins.

4) Materials, Food Safety & Coatings: What Buyers Must Get Right

Food packaging is not the place to “guess.” Your tube must be engineered for food contact safety, odor neutrality, and the distribution environment.

Food-contact compliance (baseline requirement)

Ensure paperboard, inner linings, and adhesives are selected for food-contact applications and validated for odor neutrality.

Inner barrier & grease resistance (based on your menu)

The correct inner solution reduces staining, helps the tube stay visually clean, and protects printed graphics.

Print durability for real handling

Choose print systems and surface protection that can handle abrasion and condensation without losing brand clarity.

5) Design & Customization That Drives Orders

Push pop tubes are powerful because the shape naturally elevates presentation and creates a full 360° branding area.

Branding surfaces: turn the tube into a billboard

A tube gives you a full wrap-around area for patterns, brand story, ingredient highlights, and campaign QR codes.

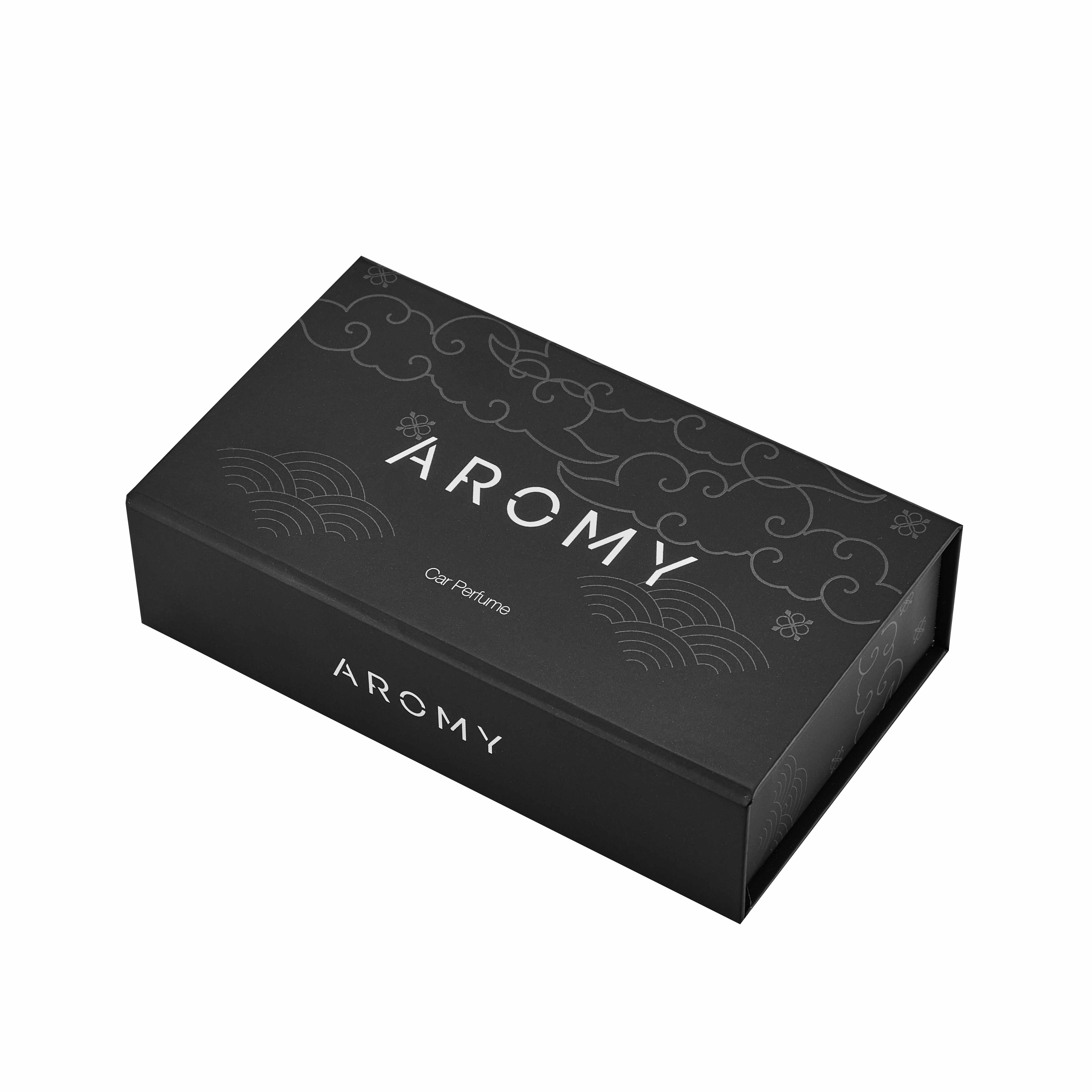

Premium finishes (when it matches your positioning)

Texture paper, selective shine, or refined emboss details can move the packaging from functional to giftable.

Optional inserts and internal supports

Inserts can stabilize the roll, separate components, or protect delicate toppings, keeping the push-up motion consistent.

Related internal category: Tube Boxes • Broader structure options: All Structures

6) Operational Fit: Packing, Delivery, Retail & Staff Workflow

A smart packaging concept can still fail if it slows down assembly or creates inconsistent outcomes during rush hours.

Assembly speed during peak times

Keep steps minimal: load the roll, secure the lid, and pack. If you add sauces or labels, standardize the workflow.

Stacking, staging, and bagging

Confirm stacking rules, handling points, and whether condensation is expected.

Retail merchandising considerations

Define the front-facing graphic orientation, barcode zone, and any tamper-evident needs.

7) Buyer Checklist: What to Include in Your RFQ (Copy/Paste Ready)

Send your manufacturer a clear RFQ to get accurate pricing and faster sampling.

RFQ checklist

- Use case: takeaway / delivery / retail / events

- Roll size: diameter + length + topping height

- Target tube size: preferred OD/height (or ask for recommendation)

- Food-contact requirements: markets sold into + compliance expectations

- Inner barrier needs: grease / moisture / condensation handling

- Lid requirements: lock level, tamper-evidence if needed

- Artwork: wrap design, barcode zone, QR needs, number of SKUs

- Finish level: matte/gloss/texture/foil/emboss

- Quantity: pilot batch + monthly forecast

- Timeline: target launch date and sampling deadline

8) Why Work with GPLPAK for Sushi Push Pop Up Tubes?

Choose a manufacturer for consistency, compliance discipline, and the ability to scale without surprises.

Built for B2B procurement

- Structure selection and production planning for repeat orders

- Food-contact material selection with odor-neutral focus

- Stable quality control for long-term programs

Options for faster launches

- Production-ready molds available for certain tube formats

- Ideal for validating market response before full customization

- Scalable supply planning once product-market fit is proven

9) FAQ: Sushi Push Pop Up Tube Packaging

Brands focused on takeaway, delivery, or retail-ready sushi gain the most.

Use roll diameter, length, topping height, and request correct tolerance for smooth push-up.

It depends on sauces, oil-rich toppings, and chilled condensation risks.

Yes, when finish placement and food-contact surfaces are handled correctly.

Assembly speed, lid security, push-up smoothness, delivery handling, and refrigerated storage behavior.

Ready to upgrade your sushi packaging?

GPLPAK can help you specify the right sushi push pop up tube packaging for your channel, menu, and brand positioning.

Hot News

Hot News